41

Instruction manual

| Types SDV-R and SDV-R-AR distribution circuit breakers

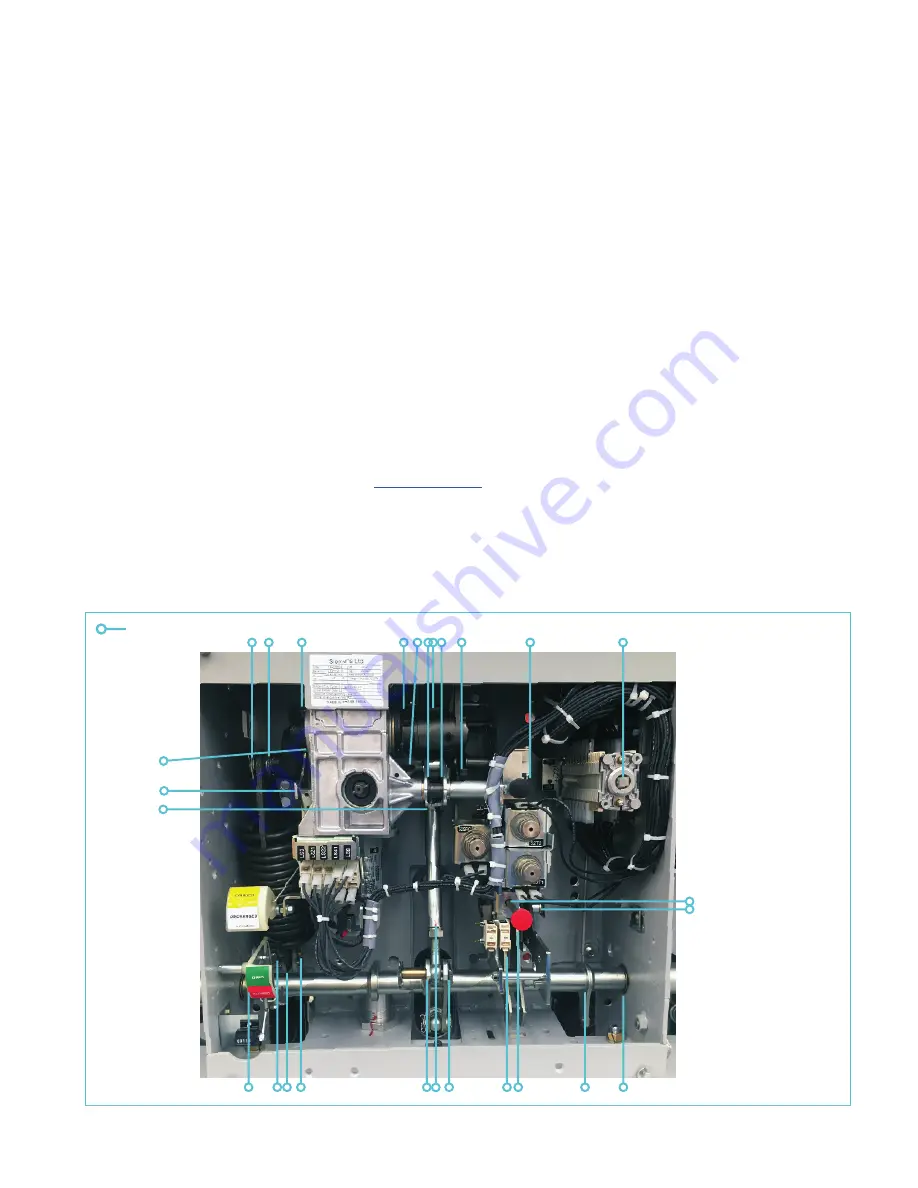

Figure 24: Operator mechanism

lubrication

Maintenance and lubrication

Table 3 on page 36 presents the

recommended maintenance intervals for the

type SDV-R distribution circuit breakers. These

intervals assume that the circuit breaker is

operated under “usual service conditions” as

discussed in ANSI/IEEE C37.04 and elaborated

in ANSI/IEEE C37.010. When actual operating

conditions are more severe, maintenance

periods may occur more frequently. The

operations counter on the front panel of the

circuit breaker records the number of

operations. The maintenance and lubrication

interval is the lesser of the number of closing

operations or the time interval since last

maintenance.

The vacuum interrupter operator mechanism

is shown in Figure 24 with the front cover

removed to show construction details. The

movable end of the closing spring is

connected to a crank arm. The movable end

of the opening spring is connected to the jack

shaft by a pull rod.

Clean the entire stored-energy operator

mechanism with a dry, lint-free cloth.

Check all components for evidence of

excessive wear. Place special attention upon

the closing spring-crank and the insulating

couplers and linkages.

Lubricate all non-electrical moving or sliding

surfaces indicated with a light coat of

synthetic grease or oil. Lubricants composed

of ester oils and lithium thickeners will be

generally compatible.

For all lubrication (except electrical moving or

sliding surfaces), use one of the following:

• Klüber Isoflex Topas L32

(part 3AX11333H)

• Klüber Isoflex Topas L32N (spray)

(part 15-172-879-201).

Source: Klüber Isoflex Topas L32 or L32N:

Klüber Lubrication North America L.P.

Fastener check

Inspect all fasteners for tightness. Both

locknuts and retaining rings are used.

Replace any fasteners that appear to have

been frequently removed and replaced.

Klüber L32 or Klüber L32N