Chapter 2

Installing the Base Station

RUGGEDCOM WIN7235

Installation Guide

12

Mounting the Base Station to a Pole

Section 2.6.2

Mounting the Base Station to a Pole

The base station can be attached to any pole (or pipe) with a 44.45 to 254 mm (1.75 to 10 in) diameter.

To mount the base station to a pole, do the following:

1. Attach the base station to the mounting bracket. For more information, refer to

the Base Station and Mounting Bracket”

.

2. Liberally apply an anti-corrosion spray to all galvanized steel components, including mounting brackets, nuts,

washers and screws.

3. Thread two steel band straps through the top and bottom slots in the mounting bracket.

4. Select a mounting location on the pole.

CAUTION!

Environmental hazard – risk of damage due to the ingress of water, dirt or debris. Make sure the

base station is oriented with the interface connections facing down.

5. Lift the base station and mounting bracket assembly and align it with the selected mounting location on the

pole.

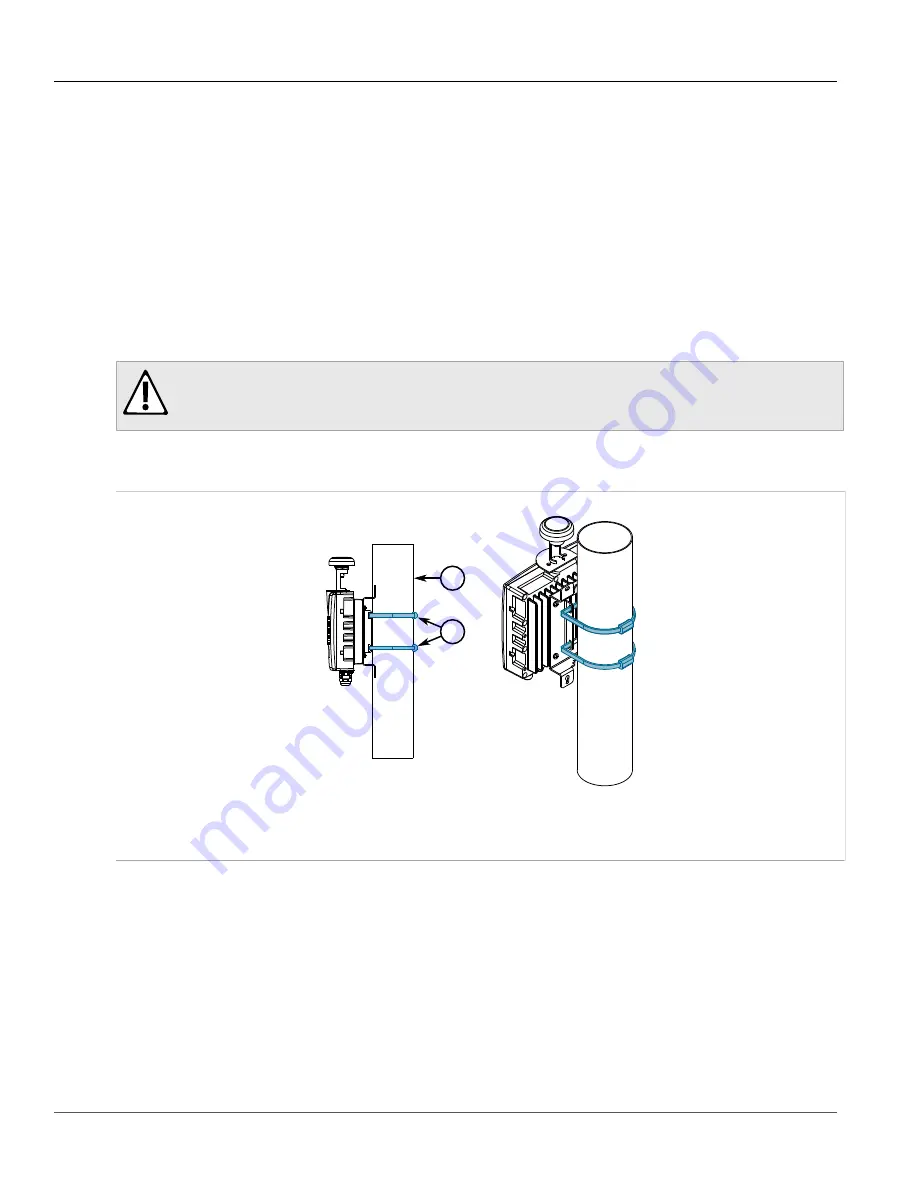

2

1

Figure 4: Securing the Base Station and Mounting Bracket Assembly to a Pole

1.

Pole

2.

Steel Band Strap

6. Wrap the bands around the pole, lock the ends together, and then tighten the screws with a 5/16 socket head

wrench. The screws must be tight enough to prevent the base station and mounting bracket from moving.

7. Liberally apply an anti-corrosion spray to all exposed screw threads.

Section 2.6.3

Assembling the Base Station and Mounting Bracket

To assemble the base station and mounting bracket together, do the following:

1. Make sure the mounting bracket is standing on its base.