Mounting

3-5

SIMATIC Panel PC 670 / 870 Operating Unit, Equipment Manual

Edition 07/02

The clamps and grub screws required for installation are supplied with the

device. Proceed as follows:

1.

Insert the complete operating unit and computing unit into the mounting

cut-out prepared as described in Section 3.1, working from the front.

2.

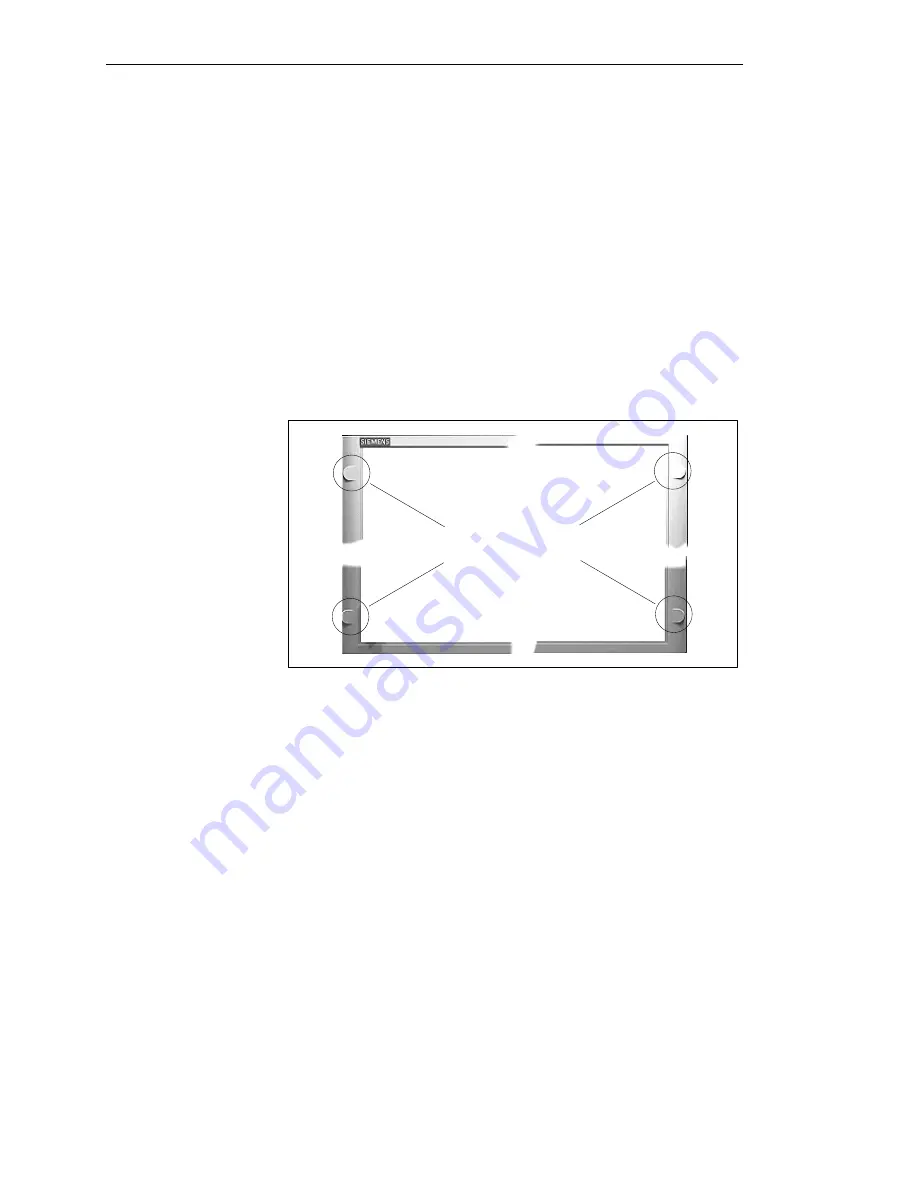

From the rear, fix the operating unit in position in the mounting cut-out

using the six clamps (see Figure 3-3) by tightening the grub screws (tor-

que 0.4 - 0.5 Nm).

The 12.1” touchscreen version is not suitable for installation with screw fi-

xings. With the other operating units, proceed as follows:

1.

Drill suitable holes around the prepared mounting cut-out (see

Section 3.1) as specified for L4 and L5 in Figure 3-3.

2.

Carefully knock out the drill hole covers on the front side of the opera-

ting unit:

Drill hole covers

3.

Working from the front, insert the complete operating unit and compu-

ting unit into the mounting cutout, ensuring that is flush with the drill ho-

les.

4.

Fix the operating unit at the drill holes using suitable screws and nuts.

Installation with

clamp fixing

Installation with

screw fixing