BA 2510

6

A5E38121849A/RS-AB, 10/2016

2.2

Lubrication

In normal operating conditions and with low loads, the lubrication of the bearings is sufficient for approximately 25,000 to

30,000 operating hours.

For higher loads due to speed and / or temperature, schedule regreasing at shorter intervals.

2.2.1

Regreasing intervals

The regreasing interval is valid for a temperature of +70 °C, measured on the surface of the housing in the vicinity of the

bearing.

Note

For temperatures above +70 °C, the regreasing interval must be reduced by half for each temperature increase of 15 K.

Note

For moderate shock loading and vibration, the regreasing interval must be reduced by 20 %.

For heavy loading, the regreasing interval must be reduced by half.

Regrease the bearing after the following number of operating hours.

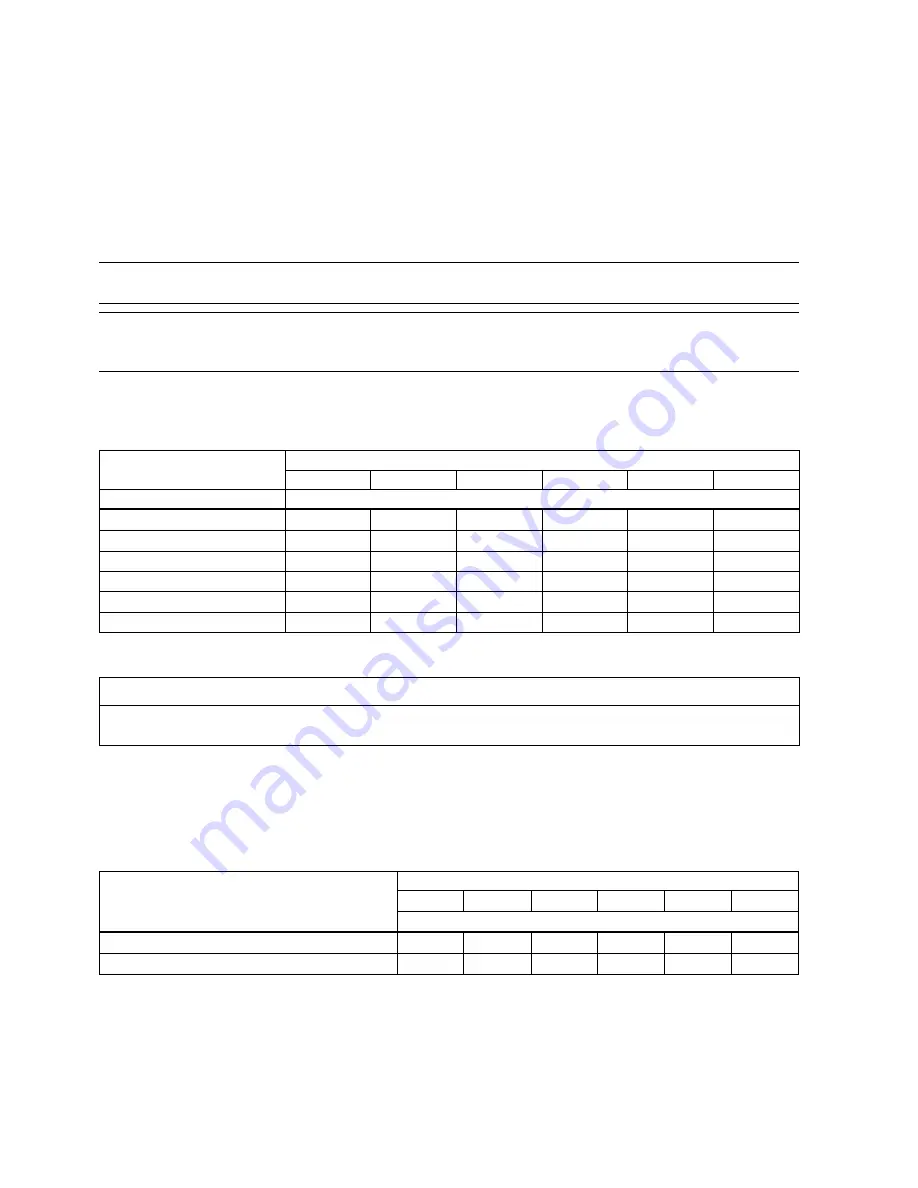

Table 2-1

Regreasing intervals in operating hours for agitator flange

Output speed n

2

Operating hours for size

68

88

108

128

148

168

[rpm]

[h]

≤ 30

29 000

29 000

29 000

29 000

29 000

18 000

31 … 50

29 000

29 000

29 000

29 000

14 000

14 000

51 … 100

29 000

29 000

16 000

16 000

10 000

10 000

101 … 150

29 000

29 000

14 000

12 000

9 000

7 000

151 … 250

18 000

16 000

10 000

9 000

5 000

5 000

251 … 400

14 000

12 000

7 000

7 000

4 000

4 000

2.2.2

Roller bearing grease

NOTICE

When regreasing do not mix greases with different soap bases

For regreasing, use lithium-saponified roller bearing grease NLGI 3/2.

Using a grease gun, inject the grease into the bearing point via the lubricating nipples provided.

The grease quantities listed in the table are guide values.

Table 2-2

Grease quantities for regreasing the agitator flange

Regreasing interval

Grease quantity for regreasing for size

68

88

108

128

148

168

[g]

After 6 months

20

20

50

60

70

70

After several years without operation

50

60

120

160

170

200