2

2.

. IIN

NS

ST

TA

AL

LL

LA

AT

TIIO

ON

N –

– M

MIIC

CR

RO

OM

MA

AS

ST

TE

ER

R V

Ve

ec

ctto

orr

E

En

ng

glliis

sh

h

© Siemens plc 1999

© Siemens plc 1999

G85139-H1751-U529-D1

G85139-H1751-U529-D1

19

19

4/8/99

4/8/99

5.

5. Ensure that the power source

Ensure that the power source supplies the correct voltage

supplies the correct voltage and is designed for the nec

and is designed for the necessary current.

essary current.

Ensure that the appropriate circuit-breakers with the specified current rating are connected between the

Ensure that the appropriate circuit-breakers with the specified current rating are connected between the

power supply and inverter see section 8.

power supply and inverter see section 8.

6.

6. For the power

For the power input, use a

input, use a 3-core cable for

3-core cable for single phase uni

single phase units or a 4-core

ts or a 4-core cable for three

cable for three phase units. For

phase units. For

the cross-section of each core see section 8.

the cross-section of each core see section 8.

7.

7. Use

Use a 4-core

a 4-core screened cable

screened cable to connect

to connect the motor.

the motor.

8.

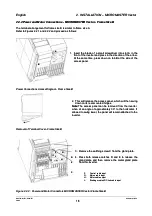

8. Carefully measure

Carefully measure and cut the

and cut the cable leads

cable leads for power c

for power connections, motor connec

onnections, motor connections and braki

tions and braking resistor

ng resistor

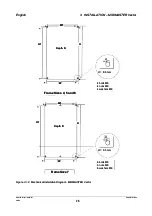

connections (if required) before feeding the screened cables through the glands in the metal gland plate

connections (if required) before feeding the screened cables through the glands in the metal gland plate

provided (see Figure 2.2.2) and securing the glands.

provided (see Figure 2.2.2) and securing the glands.

9.

9. Carefully measure and

Carefully measure and cut the cable

cut the cable leads for the

leads for the control connections

control connections (if required). Feed the

(if required). Feed the control cable

control cable

through the correct gland (see Figure 2.2.2) and secure the gland to the metal gland-plate.

through the correct gland (see Figure 2.2.2) and secure the gland to the metal gland-plate.

10.

10. Carefully feed the power and control leads through the correct holes in the inverter housing.

Carefully feed the power and control leads through the correct holes in the inverter housing.

11.

11. Secure the metal gland plate to the underside of the inverter. Fit

Secure the metal gland plate to the underside of the inverter. Fit and tighten the earth securing screw.

and tighten the earth securing screw.

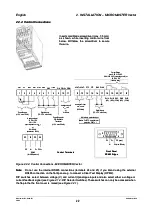

12. Connect the power input leads to the power terminals L/L1 - N/L2 (1 phase) or L/L1, N/L2, L3 (3 phase),

12. Connect the power input leads to the power terminals L/L1 - N/L2 (1 phase) or L/L1, N/L2, L3 (3 phase),

and earth (PE) shown in Figure 2.2.1 and torque down the screws.

and earth (PE) shown in Figure 2.2.1 and torque down the screws.

13. Connect the motor leads to the motor terminals U, V, W and the earth (PE) (

13. Connect the motor leads to the motor terminals U, V, W and the earth (PE) (

shown in Figure 2.2.1)

shown in Figure 2.2.1)

and

and

torque down the screws.

torque down the screws.

Note:

Note:

For operation with cables longer than 25m see section 1.3.4

For operation with cables longer than 25m see section 1.3.4

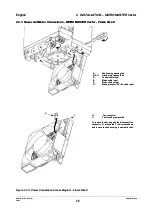

14. If required, secure Faston connectors to the braking resistor leads and fit the connectors to the B+/DC+

14. If required, secure Faston connectors to the braking resistor leads and fit the connectors to the B+/DC+

and B- terminals under the inverter.

and B- terminals under the inverter.

15.

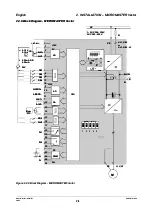

15. Connect the control leads as shown in Figures 2.2.4 and 2.2.6.

Connect the control leads as shown in Figures 2.2.4 and 2.2.6.