E

En

ng

glliis

sh

h

2

2.

. IIN

NS

ST

TA

AL

LL

LA

AT

TIIO

ON

N –

– M

MIIC

CR

RO

OM

MA

AS

ST

TE

ER

R V

Ve

ec

ctto

or

r

G85139-H1751-U529-D1

G85139-H1751-U529-D1

© Siemens plc 1999

© Siemens plc 1999

4/8/99

4/8/99

18

18

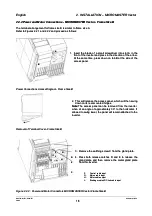

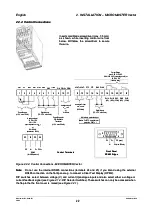

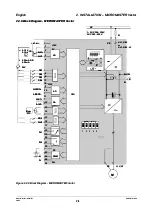

2.2.2 Power and Motor Connections -

2.2.2 Power and Motor Connections - MICROMASTER Vector - Frame Size B

MICROMASTER Vector - Frame Size B

The terminal arrangement for frame size B is similar to frame size A

The terminal arrangement for frame size B is similar to frame size A

Refer to Figures 2.2.1 and 2.2.2 and proceed as follows:

Refer to Figures 2.2.1 and 2.2.2 and proceed as follows:

B

B

A

A

Power Connections Access Diagram - Frame Size B

Power Connections Access Diagram - Frame Size B

Removal of Terminal Cover- Frame Size B

Removal of Terminal Cover- Frame Size B

D

D

E

E

C

C

F

F

G

G

J

J

H

H

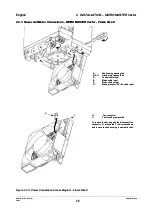

Figure 2.2.2 :

Figure 2.2.2 : Power and Motor Conn

Power and Motor Connectors MICROMASTER Vector

ectors MICROMASTER Vector Frame Size B

Frame Size B

3.

3. Remove the earthing

Remove the earthing screw C from

screw C from the gland plate.

the gland plate.

4. Press both release catches D and E to release the

4. Press both release catches D and E to release the

gland plate and then remove the metal gland plate

gland plate and then remove the metal gland plate

from the inverter.

from the inverter.

1.

1. Insert the blade of a small sc

Insert the blade of a small screwdriver into slot A in the

rewdriver into slot A in the

front of the inverter and press in the direction of the arrow.

front of the inverter and press in the direction of the arrow.

At

At the

the same

same time,

time, press

press down

down on

on tab

tab B

B at

at the

the side

side of

of the

the

access panel.

access panel.

2.

2. This will release the ac

This will release the access panel, which wil

cess panel, which will then swing

l then swing

down on its rear-mounted hinges.

down on its rear-mounted hinges.

Note:

Note:

The access panel can be removed from the inverter

The access panel can be removed from the inverter

when at an angle of approximately 30° to the horizontal. If

when at an angle of approximately 30° to the horizontal. If

allowed to swing lower, the panel will remain attached to the

allowed to swing lower, the panel will remain attached to the

inverter.

inverter.

F

F::

C

Co

on

nttrro

ol c

l ca

ab

blle i

e in

np

pu

utt

G

G::

M

Ma

aiin

ns c

s ca

ab

blle i

e in

np

pu

utt

H

H::

M

Mo

otto

or c

r ca

ab

blle o

e ou

uttp

pu

utt

J:

J:

Braking

Braking resistor/

resistor/ DC

DC link

link cable

cable input

input