89

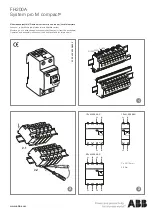

6 Maintenance

6.3.1 Maintenance Schedule

A

B

Subsection

Maintenance service

X

X

6.4.1

General Inspection

X

6.4.2

Drawing Off the SF

6

Gas

X

6.4.3

Check of Contact System

X

6.4.3.1

Dimensional Check on the Contact System

X

6.4.3.2

Replace Filter

X

6.4.4

Evacuating and Filling the Circuit-Breaker

with Gas

X

6.4.5

Check Gas Pressure Gauge

X

X

6.4.6.1

Check Function of Gas Density Monitor

X

6.4.6.2

Check of the Operating Values of the Gas

Density Monitor

X

6.4.7

Check for Leaks on Operational Circuit-

Breaker

X

X

6.4.8

Checks at Drive Mechanism

X

6.4.9

Terminal Strip

X

X

6.4.10

Anti-Condensation Heaters

X

X

6.4.11.1

Functional Check, Trip Circuits

X

X

6.4.11.2.1

Functional Check, Reclosing Lock-Out

X

X

6.4.11.2.2

Functional Check SF

6

Lockout

X

X

6.4.11.3

Functional Check, Anti-Pumping Feature

X

X

6.4.11.4

Function Check of Enforced Triple-Pole

Operation Feature

X

X

6.4.12

Check of Motor Control

X

6.4.13

Measuring the SF

6

Gas Humidity Content

X

6.4.14

Measuring the SF

6

Air Content

X

X

6.4.15

Anti-Corrosion Protection

Table 14 Maintenance Schedule

A = Checks

B = Maintenance

6 Maintenance

6.4

Work to be Carried Out in Accordance with the Maintenance Schedule

The measures compiled in the section 6.3

Maintenance Schedule

are described in detail below.

6.4.1 General

Inspection

The general inspection covers a visual check of the circuit-breaker without it having to be dismantled. The visual

check contents the following checks:

- Check the SF

6

filling with the circuit-breaker pressure gauge, see 6.4.1.1.

- contamination of insulating parts

- damage to the porcelain body

- Earth

terminal

- Number of operating cycles

6.4.1.1

Check the SF

6

Filling with the Circuit-Breaker Pressure Gauge