s

Product documentation 1D

3.8.

en

Rev. E, 10/13

page 20/42

4

Installation and operation

4.1

Safety recommendation

! WARNING

Strictly adhere to ”

”, please. In paragraph 1.2 of this Instructions,

recommendations concerning admissible use of machine and recommendations concerning required

professional knowledge that is necessary while operating heavy-current machinery.

Coverings must not be opened during operation (see also paragraph 5). Covers prevent from touching of

active or rotating parts or they are necessary for right routing of air and effective cooling.

For safety reasons, the machine can be started until the coupling is inserted at the free shaft end or after

dismantling the key at the free shaft end.

No higher speeds cannot be adjusted because this is ensured by right designed controlling and checking of

speeds. The only admissible speeds are these that are given according to output name plate.

4.2

Preparation

4.2.1

General inspection of machine

Generator must be properly inspected prior to erection (installation) with the aim to find out if there are

any damages caused during transport or storage. Any imperfections that are found out must be reported to a

supplier or transport company and must be professionally repaired. Remove preservative coating from metal

surfaces (feet, flange, free end, etc.) prior to machine seating and installation.

Insulation resistance must be inspected. Record the data measured to the operational log.

4.2.2

Locating

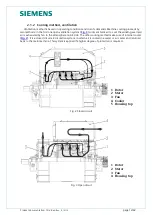

Generator must be located in the way that terminal box, bearings and accessories could be easily

approachable.

4.2.3

Foundation inspection

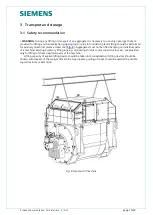

Before installing the machine, carefully check all foundation dimensions with the aid of the machine

dimension drawing and the foundation drawing, particularly - where applicable the positional accuracy of the

holes for mounting the machine on soleplates, the ducts for piping and cable.

Soft Foot Check

The test conforms to API 541-4.3.1.15

The test is made to see if there is any bending of the base frame while fixing the mounting bolts.

Prior to any mechanical running test, a check for "soft feet" will be made.

After the machine has been aligned, shimmed, and firmly secured to the test base, a dial indicator micrometer

oriented in the vertical direction shall be attached at the mounting foot to be checked.

The micrometer is then zeroed, the mounting bolt or bolts loosened at the foot and the change in micrometer

reading noted. If the micrometer reading exceeds 0.025 mm, the mounting requires cleaning or re-shimming.

This soft foot check shall be performed at each mounting foot, with the other feet secured, until all

micrometer change readings are less than 0.025 mm. If there are intermediate bases, this check shall be

performed at each interface between the machine and the test floor.

During the shop running test of the assembled machine, vibration measurements will be made with the

machine properly shimmed and securely fastened to a massive foundation or test floor stand. Elastic mounts

are only used if they are available.