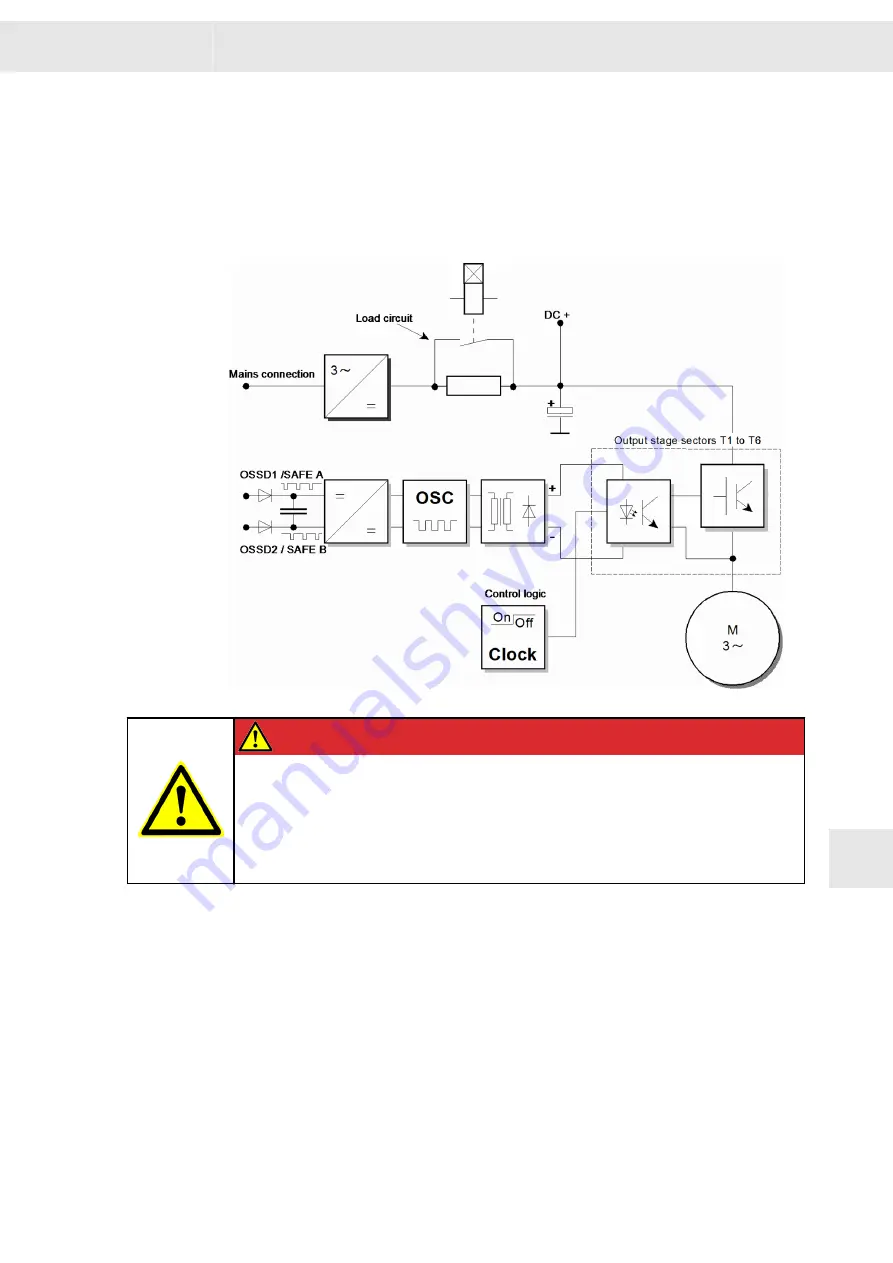

If the OSSD signals or at least one of the +24 V conductors fail, the safety circuit

switches the pulse pattern of the output stage control sectors off. The response time of

the restart lock is max. 4 ms.

The restart lock must only be controlled when

▶

the drive is at a secure standstill (stop category 2),

▶

the higher-ranking control has deactivated the drive module,

▶

(reference speed value 0)

▶

the holding brake of the motor has been arrested.

DANGER

No torque when restart lock is active

The motor cannot provide a torque when the restart lock is activated. Thus non-

self-locking drives could be released.

Non-self-locking drives as hanging loads must be blocked with a mechanical

brake.

12.2

Wiring Example

Combining a safe emergency stop command device, an OSSD safety switch device or

a light barrier with OSSD outputs and the safe switching off of the pulse patterns allows

creation of an error detection circuit, which achieves a safe stop (according to stop

function category 0+1), which meets the safety requirements according to SIL 3 (EN

ISO 13849-1). This circuit allows connecting several emergency stop devices in

parallel, which are permanently monitored.

W

Safety Circuit / Restart Lock (STO)

FC2 - Frequency converter 02192100xy

67

12

Summary of Contents for FC2

Page 4: ...Chapter Overview W 4 FC2 Frequency converter 02192100xy ...

Page 8: ...Content W 8 FC2 Frequency converter 02192100xy ...

Page 12: ...General Information W 12 FC2 Frequency converter 02192100xy 2 ...

Page 22: ...Unit Assembly Complying EMC W 22 FC2 Frequency converter 02192100xy 4 ...

Page 30: ...Technical Data W 30 FC2 Frequency converter 02192100xy 7 ...

Page 48: ...Connectors W 48 FC2 Frequency converter 02192100xy 8 ...

Page 70: ...Safety Circuit Restart Lock STO W 70 FC2 Frequency converter 02192100xy 12 ...