6

SE80/185T & SE100/185T Ignition Protected thruster assembly

1.0 - 2007

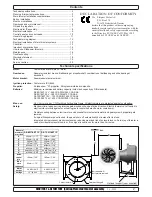

1. Try the lower-unit in the tunnel (remove the zinc anodes) first by using the gasket inside the tunnel. Try on the propellers to make

sure it is centred in the tunnel and turn freely with the same clearance from each blade to the tunnel (Fig. 1).

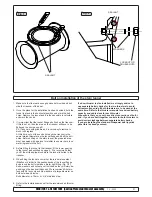

The gearleg must be fitted with the end marked P facing port and the end marked S facing starboard (Fig. 3) for the thrust direction

to correspond with the control panel. If there is no visible P or S marks, fit the gearleg with the "SLEIPNER"-casting towards the

stern/back of the boat.

2. Apply a thin layer of sealant on both sides of the gasket (7) and place it carefully on the gearhouse, making sure no sealant gets

into the bolt holes on the gearhouse (Fig 1).

3. Push the gearhouse through the main hole in the tunnel and push the gearhouse and motor-bracket gently together.

4. Fit the enclosed sealing washers to the bolts and screw the lower unit and the motor bracket together with the two provided bolts.

Tighten with 17 Nm / 12,4 lb/ft (Fig. 2).

Fitting gearhouse and motor bracket

Fig. 1

Bolt tightening forces:

Bolts (2x) holding gearhouse to bracket:

17 Nm (12,4 lb/ft)

PORT

STARBOARD

S

P

Fig. 3

Fig. 2

22

SP 75 Ti / SP 95 Ti / SP 125 Ti

2.5.1- 2007

Fig. 3

7

1. Die Mittellinie von Tunnel und Boot markieren.

SP 75 Ti / SP 95 Ti: Damit Schubrichtung und Kontrollpanel

über-einstimmen,

das Getriebegehäuse so einbauen, daß der

Ver-schluß des Getriebegehäuses (der verschraubte Verschluß

hinter einem der beiden Propeller) Richtung Steuerbord zeigt

(Fig. 5).

SP 125 Ti: Fig. 6

2. Die Löcher mit der Dichtung (7) markieren. Maße überprüfen!

Den Thruster schiffssmittig plazieren (Fig. 1). Da der Abstand

zwischen Propellern und Tunnel wegen größtmöglicher

Performance minimal konstruiert ist, müssen für eine präzise

Installation alle Löcher auf der Tunnelmittellinie liegen.

3. Im Bereich der Motorhalterung darf kein Laminat auf dem

Tunnel sein, da dies zu einem Getriebeschaden führen kann.

Liegt die Motorhalterung nicht eben auf dem Tunnel auf, so

sind sämtliche Unebenheiten in diesem Bereich abzuschleifen.

4. Bohren Sie das Zentrumsloch (ø 32 mm) und dann die

beiden Schraubenlöcher (ø 9 mm).

5. Das Getriebegehäuse mit Getriebeöl EP90 durch die Öffnung

der Ölablaßschraube (4) befüllen. Kupferdichtung (3) einsetzen.

6. Das Getriebegehäuse (ohne Zinkanoden und unteren Teil der

elastischen Kupplung) unter Verwendung der Dichtung in den

Tunnel einpassen. Den Propeller auf die Achse stecken; dieser

muß sich frei bewegen lassen und jedes Propellerblatt muß

den gleichen Abstand zum Tunnel aufweisen. Ist die Tunnel-

innenseite ungleichmäßig, etwas Sikaflex o.ä. auftragen,

damit keine undichte Stelle auftritt.

PS ! Die Durchgänge für das Öl (2) von Dichtmasse freihalten.

7. Etwas Öl oder Fett auf die O-ringe der Motorhalterung geben,

da diese sonst beim Montieren beschädigt werden können.

8. Das Getriebegehäuse durch das Hauptloch im Tunnel führen

und vorsichtig mit der Motorhalterung zusammenschieben.

9. Das Getriebegehäuse und die Motorhalterung mit Hilfe der bei-

den Bolzen verschrauben (Fig. 7).

GEA

R OI

L

EP 9

0

3

4

1

2

Fig. 4

PORT

STARBOARD

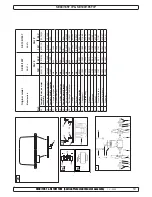

Bolt tightening forces:

Bolts (2x) holding gearhouse to bracket:

SP 75 Ti / SP 95 Ti: 17 Nm (12,4 lb/ft)

SP 125 Ti: 33 Nm (24 lb/ft)

Getriebe und Motorhalterung

D

Fitting gearhouse and motor bracket

GB

40,0mm

1,57"

Ø 11,00mm

7/16"

TUNNELS

CENTRELINE

BOATS

CENTRELINE

Ø 46,00mm

1,81"

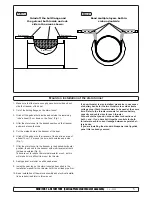

Fig. 1

SP 75 Ti

SP 95 Ti

28,0mm

1,1"

Ø 9mm

0,35"

TUNNELS

CENTRELINE

BOATS

CENTRELINE

Ø 32mm

1,26"

Fig. 2

SP125Ti

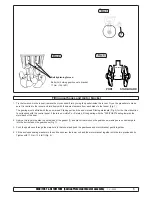

PORT

STARBOARD

S

P

Fig. 5

SP 75 Ti

SP 95 Ti

Fig. 6

SP125Ti

Fig. 7

1. Mark the centreline of the tunnel and the boats centreline. SP75Ti

/SP95Ti: The gearhouse must be fitted with the gearhouse lid (the

screwed in lid behind one of the propellers) on the starboard side of

the boat for the thrust direction to correspond with the control panel

(Fig. 5). SP 125 Ti: Fig. 6

2. Use the gearhouse gasket (7) to mark the centre of the holes and

double check the measurements. Place the thruster in the boats

centreline with the bolt hole as the centre (Fig. 1). It is absolutely

necessary that all holes are in-line with the tunnels’ centreline to

ensure precise installation, as the clearance between the

propellers and the tunnel is minimal to ensure best possible

performance.

3. There must be no casting where the motor bracket is to be placed,

as this will cause possible failure of the gearhouse. The motor

bracket must fit steady on the tunnel, if the tunnel is not smooth,

all bumps or uneven parts must be grinded smooth.

4. Drill the centre-hole ø 32mm and then the two screw-holes ø 9mm.

5. Pre-fill the gearhouse with gear oil type EP90 through the oil drain

screw (4). Make sure to get the copper gasket (3) on again.

6. Try the lower-unit in the tunnel (without the zinc anodes and the

lower part of the flexible coupling) by using the gasket inside the

tunnel. Try on the propellers to make sure they are in the middle of

the tunnel and turn freely with the same clearing from each blade to

the tunnel. Use sealant e.g. Sikaflex to ensure that no leakages

occur.

PS! Make sure that no sealant gets in to the oil-holes (2).

7. Make sure that there is some oil or grease on the O-rings in the

motor bracket before mounting it together with the gearhouse.

8. Push the gearhouse through the main hole in the tunnel and push

the gearhouse and motor-bracket gently together.

9. Screw the lower unit and the motor-bracket together with the two

provided bolts (Fig. 7).

SLEIPNER