19

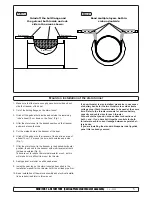

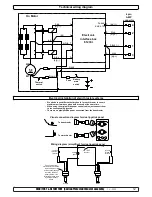

SE80/185T & SE100/185T Ignition Protected thruster assembly

1.0 - 2007

SE80/185T IP & SE100/185T IP

50

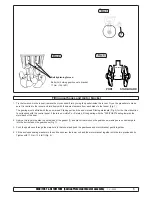

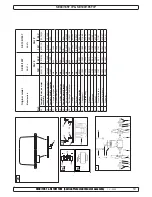

SP 75 Ti / SP 95 Ti / SP 125 Ti

2.5.1- 2007

SP 75 Ti

15

17

18

16

22

23

21

24

25

26

28

29

20

19

27

30

13

14

11

7

8

6

2

1

2

1

3

4

5

9

10

12

8

11

Re

f:

12

V

24

V

30

.

C

om

pl

et

e

el

ec

tr

ic

m

ot

or

a

ss

em

bl

y

6

01

01

1

2

6

01

01

2

4

29

.

Nu

t f

or

s

ol

en

oi

d

co

ve

r

6

88

10

6

88

10

28

.

So

le

no

id

c

ov

er

6

20

25

6

20

25

27

.

Co

m

pl

et

e

so

le

no

id

k

it

6

01

31

1

2

6

01

31

2

4

26

.

So

le

no

id

41

37

11

23

41

37

12

43

25

.

In

te

rn

al

w

iri

ng

lo

om

6

12

26

B

6

12

26

B

24

.

El

ec

tro

ni

c

co

nt

ro

l b

ox

6

12

32

i

6

12

32

i

23

.

So

le

no

id

b

ra

ck

et

k

it

6

01

35

6

01

35

22

.

Ke

y

fo

r e

le

ct

ric

m

ot

or

s

ha

ft

10

1

44

0

10

1

44

0

21

.

El

ec

tri

c

m

ot

or

N/

A

N/

A

20

.

Br

us

h

sp

rin

gs

fo

r e

le

ct

ric

m

ot

or

(k

it)

6

01

70

1

2*

6

01

70

2

4*

19

.

Br

us

he

s

fo

r e

le

ct

ric

m

ot

or

(k

it)

6

01

80

1

2*

6

01

80

2

4*

18

.

C

om

pl

et

e

fle

xi

bl

e

co

up

lin

g

7

14

50

7

14

50

17

.

Ru

bb

er

e

le

m

en

t

7

14

51

7

14

51

16

.

O

il

co

nt

ai

ne

r

w

ith

h

ol

de

r

20

0

30

0

20

0

30

0

15

.

O

il

ho

se

w

ith

h

os

e

cl

am

ps

20

0

40

0

20

0

40

0

14

.

C

om

pl

et

e

m

ot

or

b

ra

ck

et

8

05

00

8

05

00

13

.

O

-r

in

g

se

al

s

in

m

ot

or

b

ra

ck

et

7

13

40

7

13

40

12

.

C

om

pl

et

e

ge

ar

le

g

8

06

00

8

06

00

11

.

G

ea

rle

g

bo

lt

7

10

80

7

10

80

10

.

Dr

iv

e

sh

af

t s

ea

l

7

13

50

7

13

50

9.

Dr

iv

e

sh

af

t k

ey

6

14

40

6

14

40

8.

Pr

op

el

le

r s

ha

ft

se

al

6

13

50

6

13

50

7.

G

as

ke

t

8

06

10

8

06

10

6.

O

il d

ra

in

s

cr

ew

w

ith

g

as

ke

t

6

12

20

6

12

20

5.

Zi

nc

a

no

de

7

11

90

7

11

90

4.

Lo

ck

nu

t

4

12

60

4

12

60

3.

Pr

op

el

le

r w

as

he

r

7

11

81

7

11

81

2.

Pr

op

el

le

r d

riv

e

pi

n

6

12

41

6

12

41

1.

Pr

op

el

le

r

7

12

60

7

12

60

*

O

th

er

c

om

m

en

ts

:

Pl

ea

se

p

ro

vi

de

th

ru

st

er

s

er

ia

l n

um

be

r

w

he

n

or

de

rin

g

br

us

he

s

an

d

br

us

h

sp

rin

gs

.

Pa

rt

#

O

rig

in

al

m

od

el

M

od

el

p

er

io

d

SP

7

5

Ti

12

/0

4

<

12V

24V

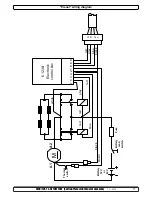

Ref:

Part #

SE 80/185T

09/07 <

Original model

Model period

12V

24V

Part #

SE 100/185T

09/07 <

9

18

1

2

3

4

5

2

1

3

4

5

6

7

8

8

10

11

12

13

13

12

14

16

17

15

19

20

20

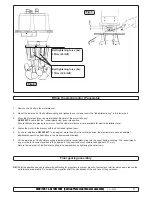

Complete IP

electric motor

assembly

6 0101 12

6 0101 24

8 0101 12

8 0101 24

19

Key for eletric motor shaft

10 1440

10 1440

10 1440

10 1440

18

Complete flexible coupling

7 1462

7 1462

N/A

N/A

17

Coupling, engine side

N/A

N/A

7 1456

16

Rubber element

N/A

N/A

7 1458

15

Coupling, gearleg side

N/A

N/A

7 1457

14

Complete motor bracket

8 0501

8 0501

N/A

N/A

13

Bolt, motor to flange

N/A

N/A

101360

101360

12

Bolt, flange to bracket

N/A

N/A

11031

11031

11

Flange

N/A

N/A

921302

921302

10

Bracket

N/A

N/A

8 0501

8 0501

9

Complete gearleg

8 0601

8 0601

8 0601

8 0601

8

Gearleg bolt

7 1080

7 1080

7 1080

7 1080

7

Driveshaft key

6 1440

6 1440

6 1440

6 1440

6

Gasket

8 0610

8 0610

8 0610

8 0610

5

Zink anode

7 1

190

7 1

190

7 1

190

7 1

190

4

Locknut

4 1260

4 1260

4 1260

4 1260

3

Propeller washer

7 1

181

7 1

181

7 1

181

7 1

181

2

Propeller drivepin

6 1241

6 1241

6 1241

6 1241

1

Propeller

7 1261

7 1261

7 1261

7 1261