Operating Instructions

Chapter

8

UE4155

8010178/TF82/2010-03-05

© SICK AG • Industrial Safety Systems • Germany • All rights reserved

41

Subject to change without notice

Configuration

8.3.4

Carrying out the PROFIsafe configuration in the FPLC hardware-configuration

program

The parameters to be set depend on the connected field device. If necessary, you must

modify the values for the bus node preassigned by the hardware-configuration program.

General parameters for the PROFIsafe configuration are:

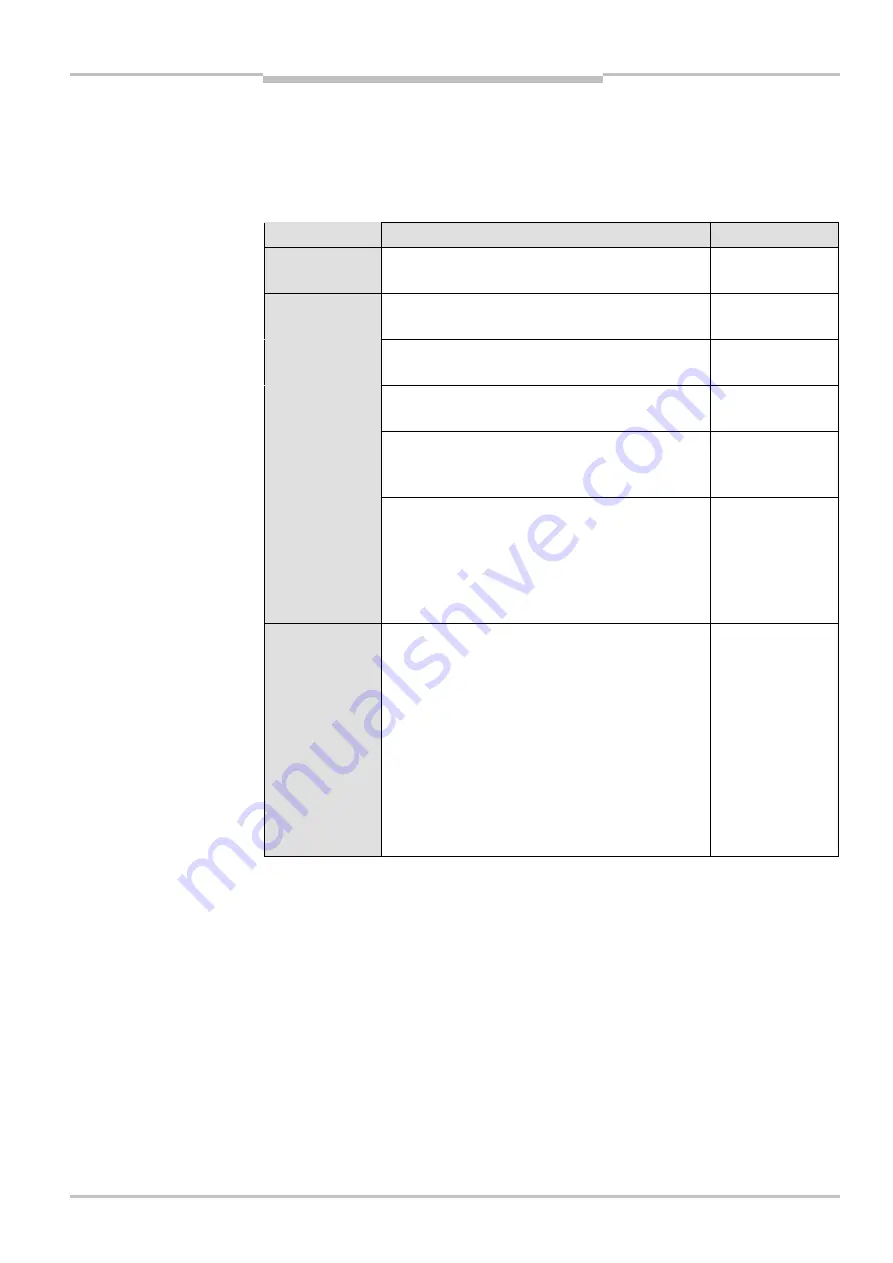

Parameter

Meaning

Setting

F_Check_SeqNr

Influences the consistency check

(CRC calculation) of the PROFIsafe telegram

Check/No check

F_SIL

Bus-node safety class (SIL1 to SIL3)

Depending on

application

F_CRC_Length

Anticipated length of the CRC checksum in the

PROFIsafe telegram

2 Byte CRC

F_Par_Version

Implemented PROFIsafe version. You cannot

change this parameter.

0

F_Source_Add

PROFIsafe source address. Must be unique in

combination with the PROFIsafe destination

address and is assigned automatically

1 to 65 534

F_Dest_Add

PROFIsafe destination address. Must be unique in

combination with the PROFIsafe source address

and is assigned automatically. Note: The

PROFIsafe address of the bus node must

correspond to this value (see chapter 8.6 on

page 45).

1 to 65 534

F_WD_Time

Monitoring time (“Watchdog time”) for the cyclic

service. If no valid PROFIsafe telegram is

exchanged between the bus node and the FPLC

within the set monitoring time, both will proceed

to the safe status, i.e. they assign themselves

failsafe values.

The monitoring time should be sufficiently long to

tolerate minor delays in communication. In the

event of an error, however, it must not unneces-

sarily delay the system response of the bus node

or that of the FPLC.

Depending on the

application from

1 to 65 535 ms

Invoke the FPLC safety program cyclically and with the highest priority. In this way you will

prevent the overall response time from becoming longer.

The planning manuals of the PROFIBUS manager and the PROFIsafe profile that you have

deployed contain more information on the definition and mode of operation of the

PROFIsafe parameters.

4)

The setting depends on the FPLC being used. The setting for a Siemens FPLC must be “No check” here.

Tab. 11: PROFIsafe

parameters to be set

Recommendation