O P E R A T I N G I N S T R U C T I O N S | T - E A S I C

®

8023072/1E22/2022-02-23 | SICK AG

Subject to change without notice

2 6

7

COMMISSIONING

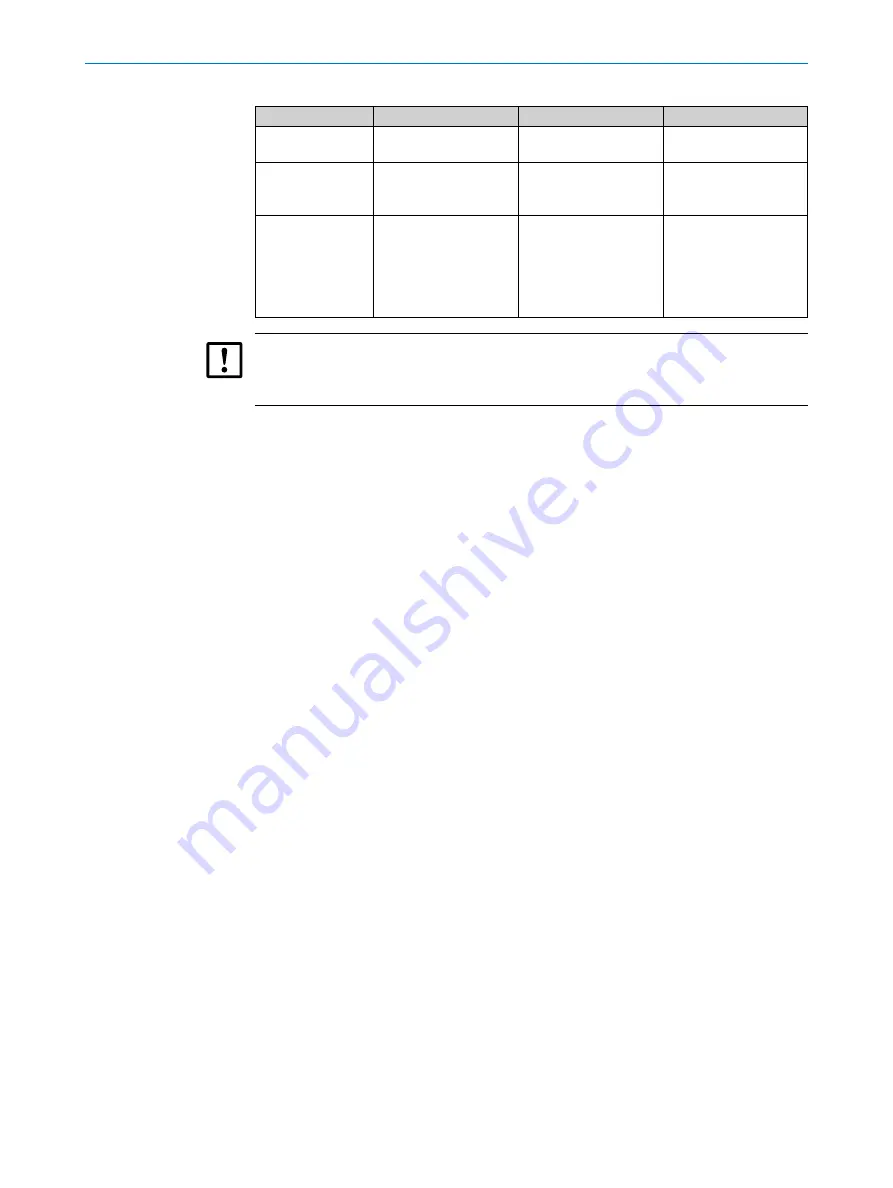

LED

Status on

Status off

Status flashing

PWR

Supply voltage is on

Supply voltage is not on Flashes during IO-Link

communication

S1

Switching output Q1

active

Switching output Q1

inactive

Device in error state

(see displayed mes-

sage)

S2

Switching output Q2

active or High signal

applied at switching

input Q2

Switching output Q2

inactive or Low signal

applied at switching

input Q2 or pulse

output active or analog

output active

Device in error

state (see displayed

message)

IMPORTANT

If the device is in the error state, S1 and S2 flash simultaneously (check displayed

message).

7.2.4

IO-Link

To operate the device via IO-Link, an IODD file, function blocks for common PLCs,

and a description of the available telegram parameters can be downloaded from

7.3

Measurement configuration

The sensor can be configured by means of various measurement parameters.

First of all, you need specify whether the sensor is to be operated in

Velocity

(relative

or

absolute

) or

Volume

( volume flow

or

counter

) mode, or whether it is to be taught-in

(Teach

).

Secondly, you can select from three different medium options (water, oil A, oil B).

There are several ways to configure

Measurement Mode

:

−

Velocity relative (%)

: The velocity is displayed as a percentage of the full scale

value.

−

Velocity absolute

: The velocity is displayed as an absolute measured value in the

unit selected for

Unit Velocity

(see

).

−

Volume flow:

The volume flow is displayed as an absolute measured value in the

unit selected for

Unit Volume Flow

(see

−

Volume counter

: The volume counter is displayed as an absolute measured value

in the unit selected for

Unit Volume

). If this measurement

mode is set, there is an option in the display to reset the volume counter (Reset

Volume). The volume counter is automatically reset each time the device is restart-

ed. To output the volume counter, pulse output must be selected in Q2.

−

Teach relative (%)

: If the medium to be measured differs from the available preset

media (water, oil A or oil B), a teach-in operation can be performed to optimize

the performance of the sensor. The flow rate is then displayed as a percentage

of the flow range between the taught-in maximum and minimum flow. The sensor

gives you the option to teach-in three different media and to store them in the sen-

“Configuring the measurement mode based on the “Teach relative”

).