11

8 007 487/ 10-10-99 Technical Description • LGT © SICK AG • Safety Systems • Germany • All rights reserved

5.3.3 Operating modes

The LGT Light Grid can be oper-

ated "with..." or "without restart in-

terlock". This means:

In the operating mode "without re-

start interlock", the contact inputs

for the machine control must be

bridged.

5.3.4 Machine control

The control switch is used to close

the main relay and test relay con-

tact again in operating mode "with

restart interlock" when the protec-

tive zone is clear again after an in-

terruption or after a test has been

successfully performed (Fig. 18).

The machine can then resume op-

eration.

A make contact must be connected

to the input terminal strip.

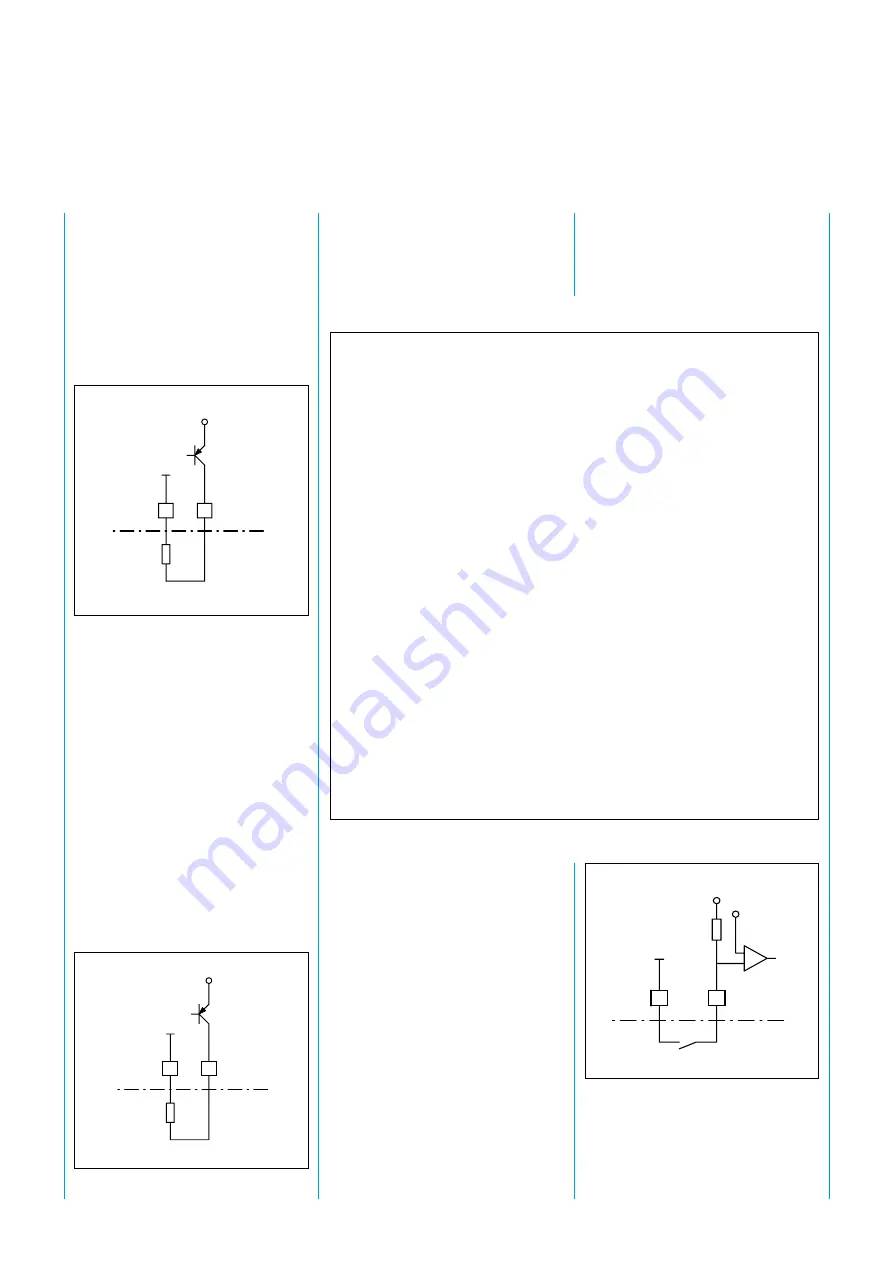

A semiconductor output provides

the exact status of the protective

zone (Fig. 16). This output has no

safety relevance.

Prot. zone free:

output live

Protective zone

interrupted:

no output

The light grid is monitored con-

tinuously for contamination. The

status is signalled by means of the

contamination semiconductor out-

put (Fig. 17).

Light grid not

contaminated:

no output

Light grid

contaminated:

output live

7

8

RL

+24V

Fig. 16. The semiconductor output gives

the actual status of the protective zone

Fig. 17. Contamination semiconductor out-

put

9

10

RL

+24V

With restart interlock

After the protective zone has been

interrupted or a test performed, the

contact of the main and auxiliary re-

lays do not close until the machine

control has been actuated. This

means that the machine cannot

resume operation until the protective

zone is clear again and the machine

control has been actuated.

If the duration of the test signal is less

than 100 ms, it is not necessary to

actuate the machine control.

The machine control must also be

actuated after the supply voltage has

been applied in this operating mode.

Without restart interlock

After the protective zone has been

interrupted or a test performed, the

contact of the main and auxiliary re-

lays close immediately after the pro-

tective zone has been cleared. It is

not necessary to actuate the machine

control. Operating modes are set via

the DIP switches on the control unit

board.

Fig. 18. The machine control is implemented

as a make contact

1

2

+24V

+4V

–

1,2 k

Ω

Control switch