- 4 -

Caution

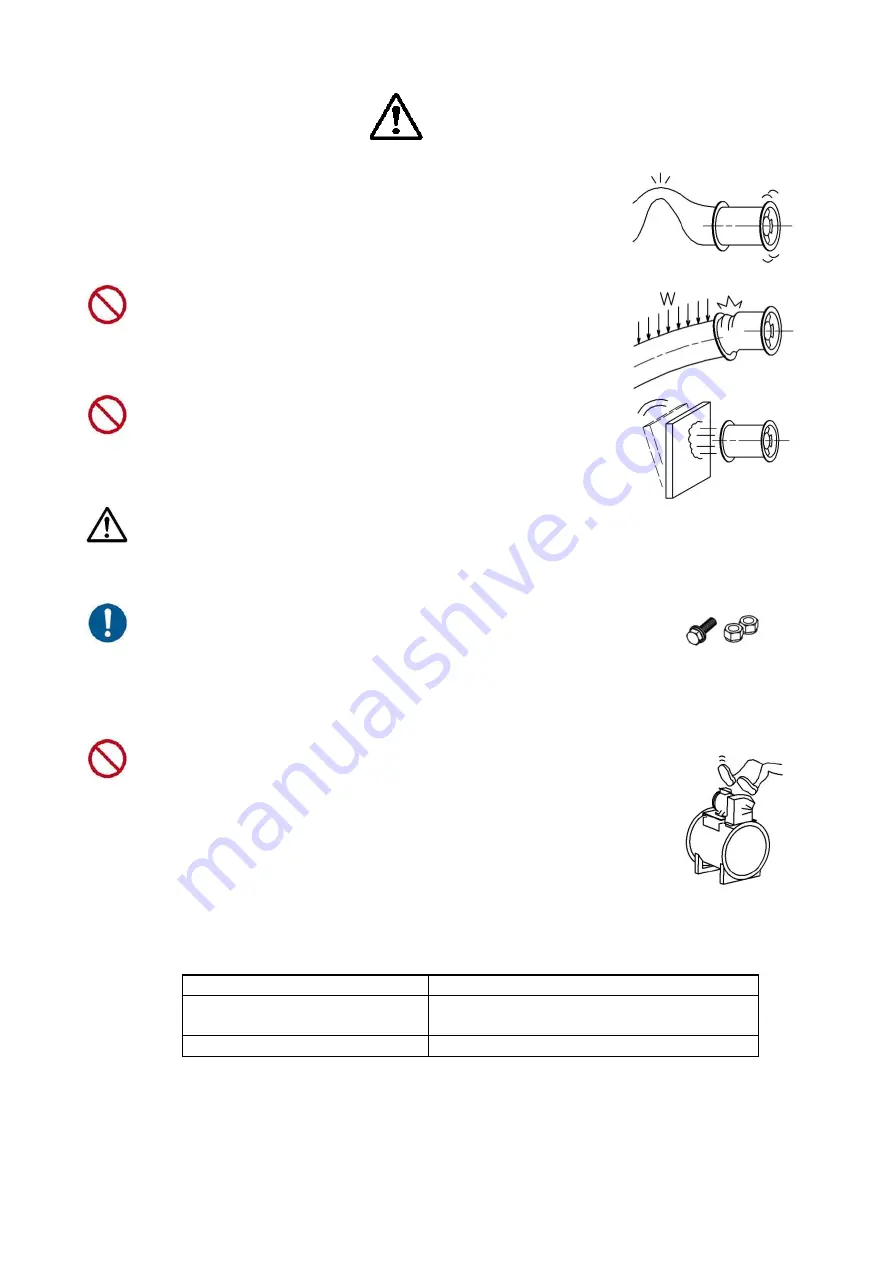

When installing piping, minimize the resistance to ducts,

pipes, etc., for air to flow smoothly. If the blower is operated

with the duct closed, it may enter stall operation status,

which may cause the impeller blade to generate abnormal

vibration, leading to an impeller damage accident.

Do not transfer the load of the duct to the blower.

Otherwise, deformation of the blower may cause contact

with the rotator, leading to an accident resulting in fire or

damage.

Remove the items that may turn over or fall due to vibration

or air flow pressure from around the blower and duct.

Otherwise, an accident may occur.

The wiring of the blower must be installed by a qualified

electrical engineer, as per the electrical equipment technical

standards and the extension rules. (Also refer to the

Operating Instructions of the motor.)

Before starting test operation, confirm that nothing is left in

the connected duct or casing or near the intake

port/discharge port, e.g., remaining materials, bolts, nuts,

tools, etc. Operating the blower with foreign material

remaining may cause an accident due to intake or rush-out,

or an accident resulting in damage.

Do not step on the blower. Otherwise, the blower may

deform or be damaged or a worker may fall.

The structure of the blower differs depending on the intake temperature. Operating the blower at a

temperature outside the range shown in the table below may cause deterioration of the belt, failure of

the bearing, and/or damage of the impeller.

Intake air temperature (°C)

Blower specification

-10 or more to 50 or less

Standard type (V-belt drive blower, motor

shaft direct-coupling)

50 or more to 150 or less

Heat-proof type (V-belt drive blower only)

Relative humidity of 90% or less