11

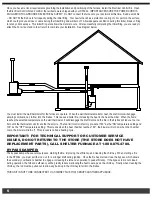

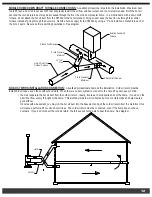

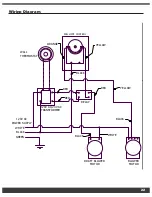

The diagrams below show typical installations through a basement window, crawl space, or wall. Notice that the heat duct and return air

duct do not contain any 90° elbows. The use of 45° or less is advised for proper air delivery.

IF 10 INCH FLEX DUCT IS USED, IT MUST NOT BE EXPOSED TO THE OUTDOORS. IT IS FOR INDOOR USE ONLY.

WARNING: RISK OF FIRE! DO NOT USE ANYTHING OTHER THAN 250° F-RATED FLEX DUCT!

GROUND FURNACE TO GROUNDING ROD AND LEG OF FURNACE!

IMPORTANT: FOR TECHNICAL SUPPORT OR CUSTOMER SERVICE

ISSUES, DO NOT RETURN TO THE STORE (THE STORE DOES NOT HAVE

REPLACEMENT PARTS), CALL SHELTER FURNACE AT 1-800-875-4788.

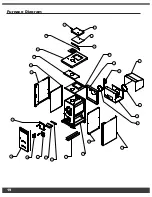

TYPES OF INSTALLATION:

Your Shelter Furnace is designed to be a supplemental or central heating source for your home. This wood/coal burning furnace may be

installed parallel with a properly operating electric, gas, or oil-fired central furnace that is listed or certified in accordance with a nationally

recognized safety standard within installation clearances as specified on the Shelter Furnace nameplate. When in a parallel installation

the static pressure of the central furnace plenum may not exceed .15 inches water column, and maximum setting on central furnace limit

switch is 182° F. With the SF3042 wood and coal burning furnace in an “Interconnection Arrangement” your Shelter Furnace should

be upstream from the central furnace. The Shelter Furnace warm air supply should never be connected to the return air for the central

furnace. A QUALIFIED INSTALLER SHOULD PERFORM INSTALLATION.

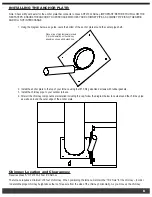

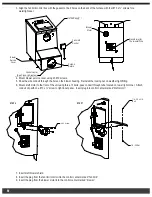

CENTRAL DUCT CONNECTIONS:

A qualified professional should do the installation. Maximum run should be 25 feet. A duct run

in excess of 25 feet will greatly restrict the air flow and heat output, therefore is not recommended. When connecting the SF3042 to a

central duct system, avoid 90° elbows. As with any furnace, the more turns and branches in the ducting limit the airflow delivery. DO

NOT USE FLEX DUCT OUTSIDE.

Run 10 inch insulated galvanized hot air duct from the outside furnace through a window or wall of the house. Once inside, you may use

250 degree rated insulated flexible hot air duct, to the central duct system for the home. Connect the duct with a 45° elbow or at an angle

so the hot air from the SF3042 is delivered down stream. This will ensure proper airflow into the duct system. Avoid delivering the hot air

through the air conditioning coil, as this will cause an obstruction, reducing the amount of heat output. DO NOT REDUCE THE SIZE OF

THE HOT AIR DUCT. As with any furnace, longer runs and more turns and branches in the ducting greatly reduce the airflow and heat

output. Use of 90° elbows is not recommended.

The 12 inch cold air return duct must run to the house to prevent pressurization of the home. Failure to connect the cold air return will

cause the furnace not to operate. NEVER REDUCE THE SIZE OF THE RETURN. Reducing the size of the cold air return will restrict

the hot air flow and put excess pressure on the blower motor. You may terminate the cold air return where you enter the house. This will

provide adequate circulation within the home. See diagram.

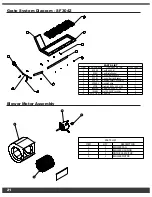

RETURN AIR DUCT

SUPPLY DUCT

OPEN/CLOSE

RETURN DAMPERS

3 PLACES

BACKDRAFT DAMPERS

Return Air Duct

Backdraft Dampers

Open/Close

Return Dampers

3 Places

Supply Duct