17

CAUTION:

• INSPECT FLUE PIPES, JOINTS AND SEALS REGULARLY TO ENSURE THAT SMOKE AND FLUE GASES ARE NOT

DRAWING INTO, AND CIRCULATED BY THE AIR-CIRCULATION SYSTEM.

• CLEANING OF THE HEAT EXCHANGER, FLUE PIPE, CHIMNEY AND DRAFT INDUCER (IF USED), IS ESPECIALLY

IMPORTANT AT THE END OF THE HEATING SEASON TO MINIMIZE CORROSION DURING THE SUMMER MONTHS

CAUSED BY ACCUMULATED ASH.

• Do not use chemicals to start the fire.

• Do not burn garbage, gasoline, naphtha, engine oil, or other flammable liquids/inappropriate materials.

Maintaining

Your

Furnace:

At the beginning of each heating season, take time to thoroughly check your furnace and chimney system. Make sure there are no leaks

where the metal panels are joined or at the caulk lines. Should you find a leak, hi-temp silicone will correct the problem. Check the doors

for signs of rust. Should rust develop, lightly sand, with sandpaper or steel wool, the surface and follow up with black, high temperature

paint to keep the doors looking new. Check the gaskets, if they are frayed and burnt, replace the gasket. Check the firebricks for

breakage or crumbling, and replace as needed. Check the chimney pipe for signs of creosote formation, if you find creosote, thoroughly

clean the chimney system replacing the chimney cap securely so rain or snow does not run down the chimney into the firebox. If the cap

is removed for any length of time when the furnace is not in use, cover the pipe so no moisture gets into the firebox. Check the chimney

cap for holes or loosened connections, replace and secure as necessary. Check the grates for signs of wear and replace as needed.

Check the heat duct and cold air return to be sure they have not become loose or been damaged. If so, tighten or replace as needed.

Check ductwork for any air leaks. Remove any accumulated ashes at the end of the season. By following these procedures, your

furnace will provide many years of trouble-free service.

IMPORTANT: FOR TECHNICAL SUPPORT OR CUSTOMER SERVICE

ISSUES, DO NOT RETURN TO THE STORE (THE STORE DOES NOT HAVE

REPLACEMENT PARTS), CALL SHELTER FURNACE AT 1-800-875-4788.

ALWAYS:

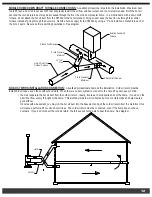

• Locate the Shelter Furnace on a level, solid, non-combustible surface.

• Follow local codes concerning installation requirements.

• Connect power cord to a grounded 110 outlet.

• Connect cold air return to the house.

• Use Class “A” HT2100 All Fuel 6 inch chimney.

• Follow guidelines within this manual regarding burn procedures.

• Operate furnace with fuel door and ash doors closed.

• Inspect the furnace several times a year to ensure furnace caulking is adequate.

• Inspect chimney pipe for creosote formation.

• Use dry, seasoned hardwood, maximum length of 28 inches, and always keep your wood covered.

• Have access to a backup generator in case of power failure, minimum of 2000 watts.

NEVER:

• Allow anyone to operate the furnace that is not familiar with the unit.

• Operate the furnace with the spin draft wide open unattended.

• Operate with fuel or ash doors open.

• Use gasoline, oil, or any other flammable liquid to start or maintain the fire.

• Burn garbage, plastic, wood containing glue, paraffin, or wood that has been treated with chemical preservatives.

• Operate your furnace without a backup power supply, or generator.

• Fuel your furnace with wet, unseasoned wood.

• Use 90° elbows when running ductwork.

• Operate the furnace without the chimney attached.

• Alter the furnace in any way.