15

ignition. Heat resistant gloves are recommended when opening the fuel door, regulating the spin draft or emptying the ash pan.

DISPOSAL OF ASHES:

Remove the ashes from your Shelter Furnace at least once a day, or as often as necessary to ensure the ashes do not build up to the

height of the grate system. If ash builds up to the level of the grate, it will cause premature failure of the grates, which voids the warranty

on the grate system. The airflow was designed to keep the grates cool, in addition to providing the firebox with warmed air for better

combustion. If the ash level is improperly maintained, the firebox will be starved for air, greatly reducing the efficiency and heat output

of the furnace. Discard the hot ashes in a safe manner. Remove the ash pan from the furnace and dump the hot ashes into an airtight

metal container, place the container on a non-combustible surface, well away from combustible materials, pending final disposal. If the

ashes are disposed of by burial in soil, or otherwise locally dispersed, they should stay in the closed metal container until all cinders have

thoroughly cooled.

ALWAYS KEEP YOUR WOOD COVERED YEAR ROUND. DRY WOOD WILL PRODUCE A HIGHER BTU OUTPUT AND A LONGER

BURN TIME.

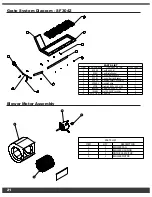

HEAT DUMP AND FUSE LINK SYSTEM:

The Shelter SF3042 has a patented automatic safety feature, the Heat Dump Release System. In the case of a power failure, the heat

dump release will open the spring-loaded lid when the internal furnace temperature reaches 370° F. The heat sensitive fuse link, located

within the top of the heat chamber, causes the lid to open, allowing the excess heat to escape. This safety feature is designed to activate

before any extreme heat can damage the furnace.

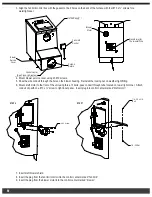

In the case of a power failure, connect your Shelter Furnace to a generator immediately. If the heat dump release lid should open, do

not continue to burn the furnace. DO NOT UNPLUG THE FURNACE. Close the draft dampers and set the wall thermostat to the lowest

possible temperature. DO NOT add fuel (either wood or coal), which will allow the fire to die. Pull out by-pass rod. After the electricity is

restored, replace the fuse link before resuming normal operation.

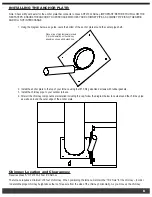

REPLACING THE FUSE LINK:

Remove the hex nut on top of the release lid and pull the bolt down thru the lid. Remove the

separated fuse link pieces and connect the new fuse link to the shaft inside the furnace heat chamber. Connect the other end of the fuse

link to the bolt that goes thru the lid. Feed the bolt thru the lid and replace the hex nut onto the bolt on top of the lid. As a precaution,

always have a replacement fuse link on hand.

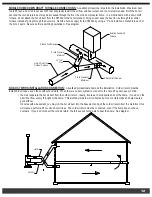

WARNING: Never disengage the patented Heat Dump Fuse Link feature. This will void all warranties. Never put anything on top of the

release lid. The area must be kept free of any obstructions. A visual inspection by factory personnel can easily determine if the proper

steps were taken if a furnace over-heats. If the furnace is found to be deliberately improperly used, all warranties will be void.

To order a replacement Fuse Link (Part # FCFL370): call 1-800-875-4788.

One replacement fuse link will be included in the hardware pack for your furnace.

OPEN

CLOSED