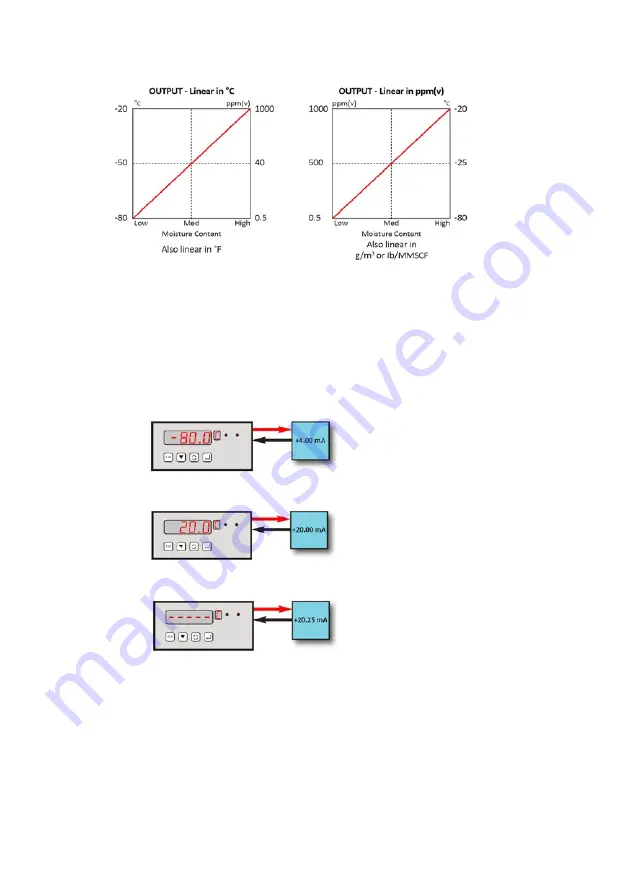

OUTPUT - Linear in °C

OUTPUT - Linear in ppm(v)

For example:

For a range of -80°C to + 20°C dewpoint the analogue output will be at its

minimum when the reading is at -80°C dewpoint and at its maximum when the

reading is at +20°C dewpoint.

Furthermore the factory default configuration is that the output current ranges

from 4 to 20 mA. Therefore using the above example the port will output 4mA

when the AcuTrak displays -80°C dewpoint.

And 20mA when the AcuTrak di20°C dewpoint.

If a sensor is detected as short circuit then the current output will rise to

+20.25mA.

If required there is facility to change the output current calibration points at either

end of the scale to attain a more focused signal.

8.5.1 Spanning the mA Output

It is possible to change the output current calibration points at either end of the

range to attain a more focused retransmitted signal.

31