Precautions

•

Before installation, be sure to turn off the power.

•

Use gloves to protect your hand from being cut by the angle

and the chassis.

•

Connect all the cables securely. When connecting or

disconnecting the cables, be careful not to apply stress to the

cables. (It may cause disconnection.)

•

Ground the human body to prevent against troubles and dust

adhesion to the LCD by static electricity. When assembling the

LCD, use a discharge blower to prevent against dust intrusion.

•

Be careful to the high voltage of the invertor PWB transformer.

•

About placing top cabinet with LCD panel side down, Please

use a clean dust free clothe to protect the touch panel and LCD

area.

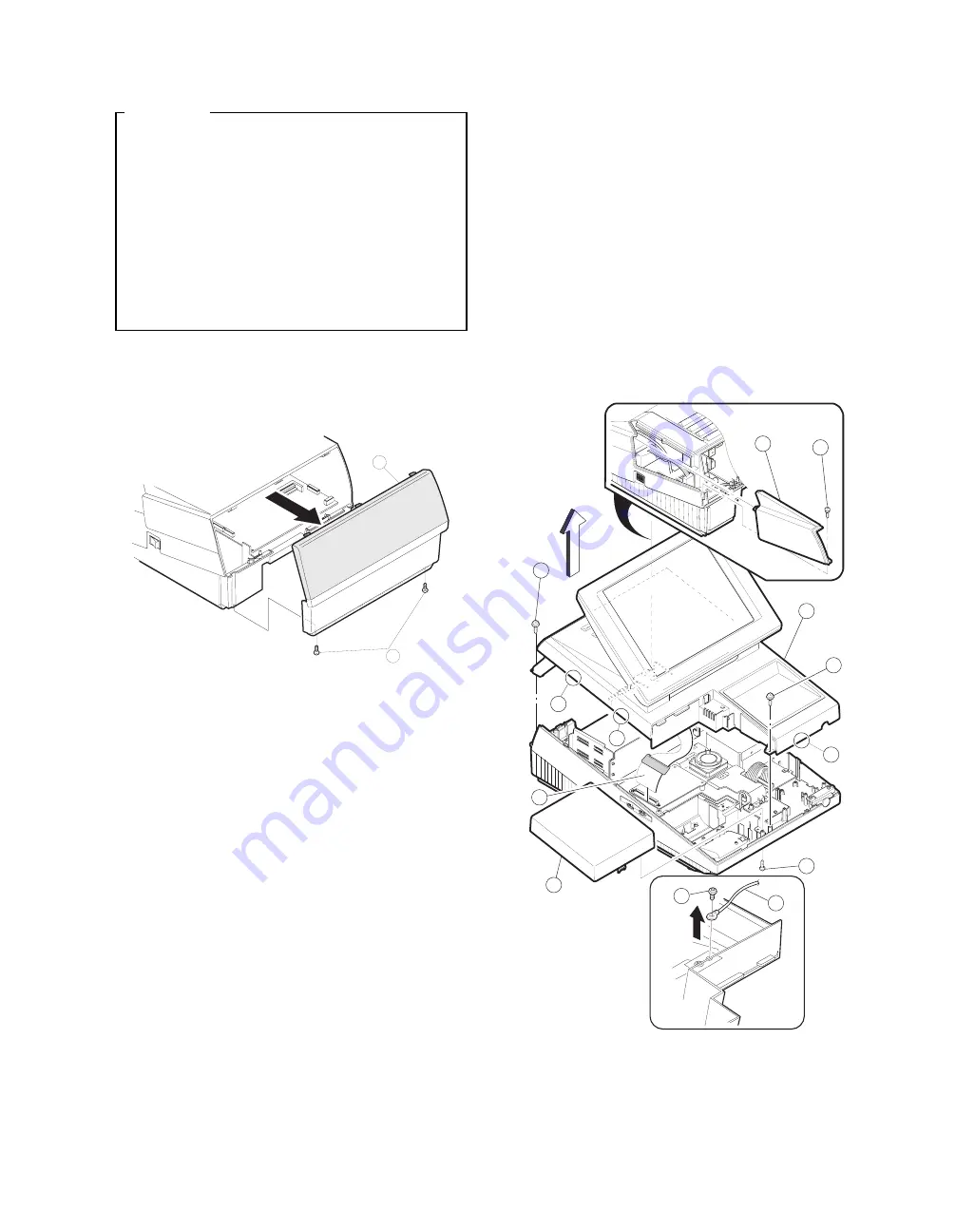

1. Removing the Rear display filter

1) Remove the two Screws

1

.

2) Remove the Rear display filter

2

.

2. Replacing the Rear display filter

Install the Rear display filter in the reverse order of removing.

3. Removing the Top cabinet

1) Remove the two Screws

1

.

2) Remove the Side cabinet

7

.

2) Remove the Screw

2

.

3) Remove the Printer cover

3

.

4) Remove the Screw

4

.

5) Remove the Top cabinet

8

.

a) Release the latches

a

,

b

and

c

in that order. Slide the

upper cabinet to the right and release the latch on the right.

b) Lift the top cabinet and put it straight in the direction of arrow

A. ( Be careful not to pull the cable between the LCD I/F PWB

of the top cabinet and the MAIN PWB of the Bottom cabinet.)

c) Pull and remove the following cables between the LCD I/F

PWB of the top cabinet and the MAIN PWB of the Bottom

cabinet.

•

LCD Cable

5

: MAIN PWB : CN11

•

Earth wire

6

.

4. Replacing the Top cabinet

Install the top cabinet in the reverse order of removing. Before install-

ing, make sure that each connector is connected securely.

1

2

A

1

7

3

5

2

6

4

1

8

9

a

b

c

– 1 –