MX-M350/M450 N/U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 68

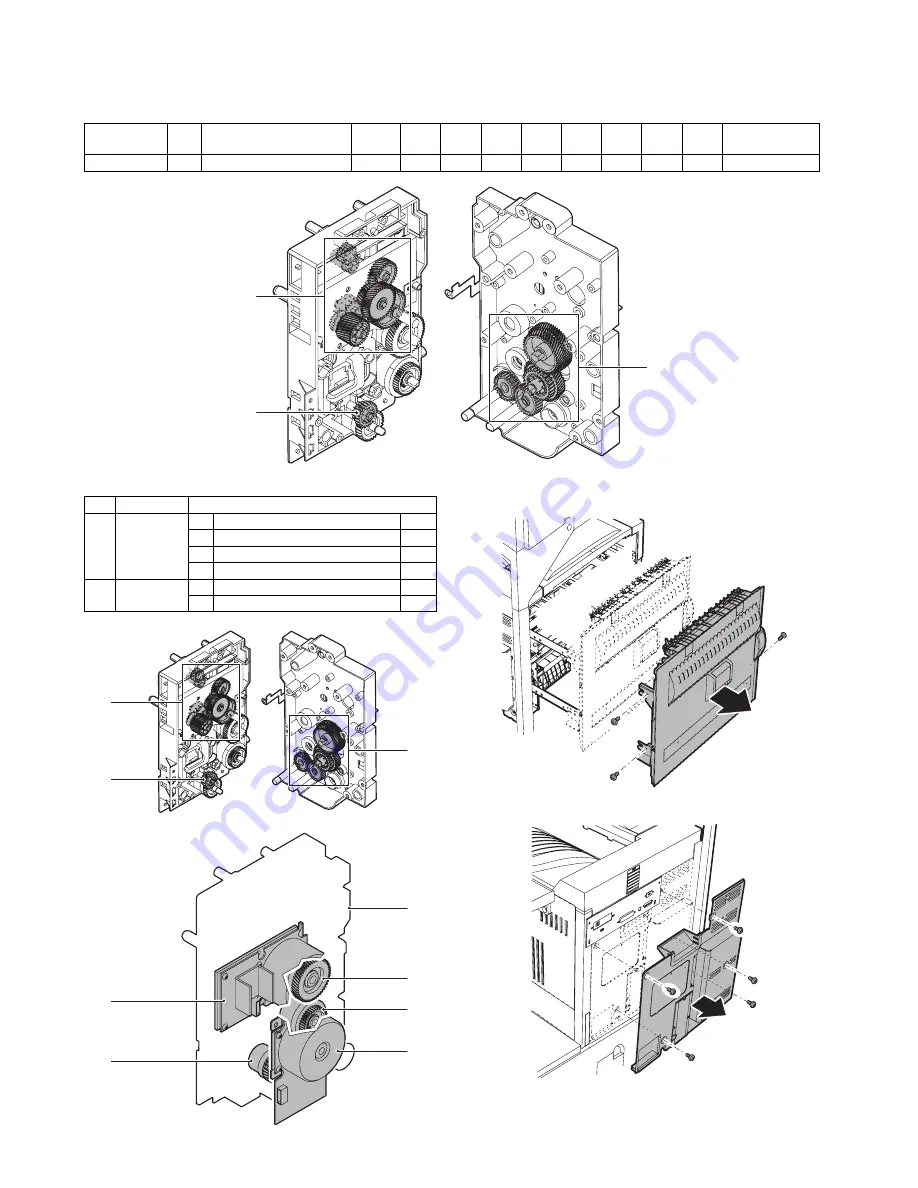

10. Drive section

A. Maintenance and parts replacement

(1) Maintenance list

(2) Maintenance and parts replacement

a. Drive unit

1) Remove the screw, and remove the left door.

2) Remove the screw, and remove the rear cabinet.

Unit name

No.

Part name

When

calling

100K

200K

300K

400K

500K

600K

700K

800K

Remark

Drive section

1

Gears (Specified position)

✕

✩

✩

✩

✩

✩

✩

✩

✩

1

1

1

No.

Unit

Parts

a

Drive unit

1

Gears

✕✩

2

Paper cassette paper feed clutch

3

Paper transport clutch

4

Resist roller clutch

b

1

Drum motor

2

Main motor

a-2

b-1

a-4

a

a-3

b-2

a-1

a-1

a-1

Summary of Contents for MX-M350

Page 232: ...MX M350 M450 N U MACHINE OPERATION 10 6 C Configuration report Test page Model name ...

Page 271: ...Memo ...

Page 272: ...Memo ...

Page 273: ...Memo ...