AR-M205 SIMULATIONS 7-1

[7] SIMULATIONS

1. Entering the simulation mode

Perform the following procedure to enter the simulation mode.

"#" key

Interrupt key

"C" key

Interrupt key

Main code

Start key

Sub code

Start key

2. Canceling the simulation mode

When the clear all key is pressed, the simulation mode is cancelled.

When the interruption key is pressed, the process is interrupted and the

screen returns to the sub code entering display.

*

After canceling the simulation mode, be sure to turn OFF/ON the

power and check the operation.

Note: If the machine is terminated by a jam error or paper empty during

copying in the adjustment by the simulation, recopying is required.

3. List of simulations

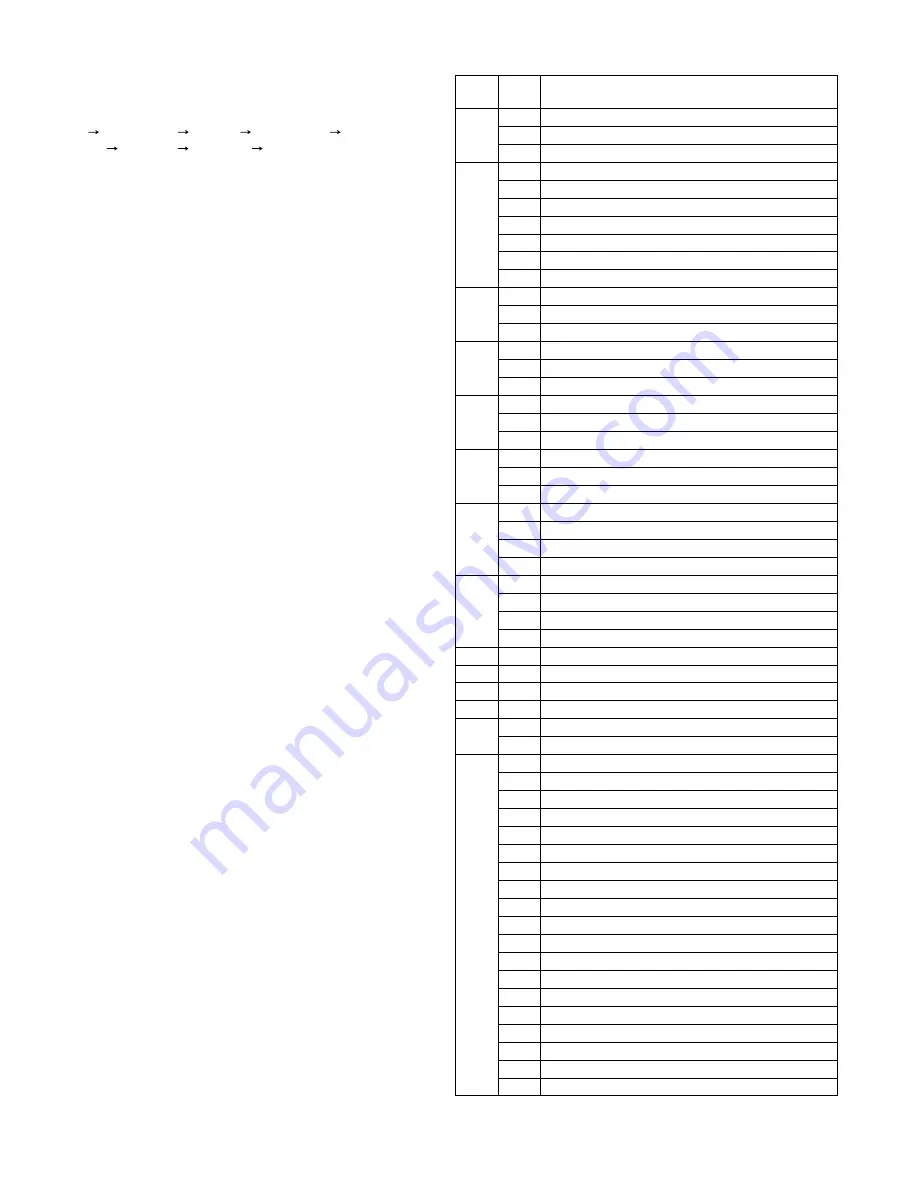

Main

code

Sub

code

Contents

01

01

Mirror scanning operation

02

Mirror home position sensor (MHPS) status display

06

Mirror scanning operation aging

02

01

Single paper feeder (SPF) aging

02

SPF sensor status display

03

SPF motor operation check

08

SPG paper feed solenoid operation check

09

RSPF reverse solenoid operation check

10

RSPF paper exit gate solenoid operation check

11

SPF PS release solenoid operation check

03

02

Shifter sensors status display

03

Shifter operation check

11

Shifter home position check

05

01

Operation panel display check

02

Fusing lamp and cooling fan operation check

03

Copy lamp lighting check

06

01

Paper feed solenoid operation check

02

Resist roller solenoid operation check

10

Main cassette semicircular roller cleaning

07

01

Warm-up display and aging with jam

06

Intermittent aging

08

Shifting with warm-up display

08

01

Developing bias output

02

Main charger output (Grid = HIGH)

03

Main charger output (Grid = LOW)

06

Transfer charger output

09

01

Duplex motor forward rotation check

02

Duplex motor reverse rotation check

04

Duplex motor RPM adjustment

05

Duplex motor switchback time adjustment

10

-

Toner motor operation

14

-

Trouble cancel (except for U2)

16

-

U2 trouble cancel

20

01

Maintenance counter clear

21

01

Maintenance cycle setting

02

Mini maintenance cycle setting

22

01

Maintenance counter display

02

Maintenance preset display

03

Jam memory display

04

Jam total counter display

05

Total counter display

06

Developing counter display

07

Mini maintenance preset display

08

SPF counter display

09

Paper feed counter display

12

Drum counter display

13

CRUM type display

14

P-ROM version display

15

Trouble memory display

16

Duplex print counter display

17

Copy counter display

18

Printer counter display

19

Scanner mode counter display

21

Scanner counter display

22

SPF jam counter display

!"#$