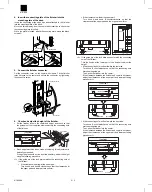

A. Upper paper transport section

1) Paper transport

By rotating the main driving motor (FM), the transport rollers in the

finisher are driven.

2) Paper discharge gate 1 (1)

The paper discharge gate 1 (1) is operated by the paper discharge

gate 1 solenoid (OG1SL), to select between the routes for paper

discharge to the tray 1 (8) and transport to the tray 2 (5)/staple tray.

3) Paper discharge gate 2 (6)

The paper discharge gate 2 (6) is operated by the paper discharge

gate 2 solenoid (OG2SL) to select between the routes for paper

discharge to the tray 2 (5) and transport to the staple tray.

4) Trays 1 (8) and 2 (5) paper discharge operation

When paper is discharged to tray 1 (8) and tray 2 (5), tray 12 reduc-

tion clutch (11) is operated at the paper discharging timing to reduce

the speed of paper discharge rollers 1 and 2, improving the accuracy

of paper alignment in tray 1 (8) and tray 2 (5).

5) Trays 1 (10) and 2 (7) paper full detection

Whether the trays 1 (10) and 2 (7) are filled with paper is detected by

the tray 1 and 2 paper full sensor.

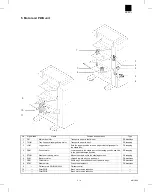

No.

Signal name

Name

(1)

—

Paper discharge gate 1

(2)

PFD2

Transport sensor 2

(3)

INPD

Paper entry sensor

(4)

PFD4

Transport sensor 4

(5)

—

Tray 2

(6)

—

Paper discharge gate 2

(7)

T2PF

Tray 2 paper full detecting sensor

(8)

—

Tray 1

(9)

PFD3

Transport sensor 3

(10)

T1PF

Tray paper full sensor

(11)

T12CL

Trays 1 and 2 deceleration clutch

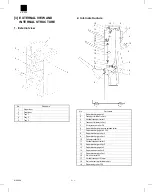

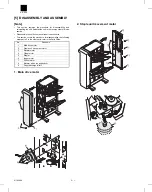

B. Staple tray

1) Jogger motor (JGM)

The jogger motor is driven when the paper is fed into the staple tray,

to operate the jog plates F and R so as to align the sideways edge of

the paper.

2) Paddler (11)

The paddler clutch (PDCL) is turned ON when the paper is fed into

the staple tray, to give the paddler a full turn so as to drop the paper

downward (pusher), thus achieving alignment in the vertical direction.

3) Pusher motor (PSM)

With the pusher motor rotating, the paper stored inside the staple tray

is lowered from the home position (discharge position) to the stapling

position; after stapling, the paper inside the staple tray is elevated

from the stapling position to the home position.

4) Staple unit movement motor (STUM)

The staple unit is moved to the stapling positions (front, far end, 2

centers) by the staple unit motor.

5) Staple tray paper discharge

When the paper delivery roller pressure release clutch (STORCL) is

turned ON, the paper delivery pressure release roller (4) is pres-

surized through the cam to discharge the paper from the stable tray.

6) Paper discharge gate 3 (5)

The paper discharge gate 3 (5) is operated by the paper discharge

gate 3 solenoid (OG3SL) to switch over the routes of paper inside the

staple tray between the paper discharge side and the staple side of

the off-set tray.

7) Tray 3 paper discharge motor

The tray paper discharge motor (12) is rotated to drive the paper

discharge rollers 3 and 4 to discharge paper to the tray 3.

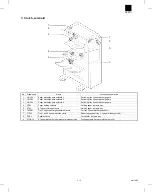

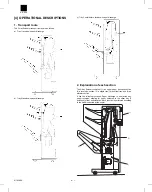

No.

Signal name

Part name

(1)

—

Short path switching gate

(2)

—

Paper discharge roller 3

(3)

—

Pusher

(4)

—

Paper delivery pressure release roller

(5)

—

Paper discharge gate 3

(6)

STPD

Staple tray paper detection sensor

(7)

—

Staple unit

(8)

T3ORSL

Paper discharge roller 4

(9)

T3OD

Tray 3 paper discharge sensor

(10)

STID

Staple tray paper entry sensor

(11)

—

Paddler

(12)

T3OH

Tray 3 paper discharge motor

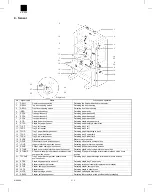

(11)

(10)

(1)

(2)

(3)

(9)

(8)

(6)

(5)

(4)

(7)

(To staple tray)

(11)

(10)

(9)

(8)

(6)

(5)

(4)

(7)

(1)

(2)

(12)

AR-FN3

4 – 2

8/19/1999

Summary of Contents for AR-FN3

Page 20: ...15 15 15 15 16 AR FN3 8 19 1999 5 7 ...

Page 27: ... Rollers Paper guides AR FN3 7 2 8 19 1999 ...

Page 28: ...AR FN3 8 19 1999 7 3 ...

Page 29: ... Gears Others Sensors Belts AR FN3 7 4 8 19 1999 ...

Page 51: ...3 Main PWB page arrangement 1 2 AR FN3 10 9 8 6 1999 ...

Page 52: ...Main PWB page arrangement 2 2 AR FN3 8 6 1999 10 10 ...