AR-203E/5420/M200/M201 USER PROGRAM 12 - 1

[12] USER PROGRAM

The conditions of factory setting can be changed according to the

use conditions.

1. Functions that can be set with user

programs

Toner save mode

Reduces toner consumption by approximately 10%.

Power save modes

The unit has two power save modes of operation: preheat mode

and auto power shut-off mode.

Preheat mode

When the unit enters the preheat mode, the power save (

) indi-

cator will light up and other indicators will remain on or off as

before. In this condition, the fuser in the unit is maintained at a

lower heat level, thereby saving power. To copy from the preheat

mode, make desired copier selections and press the start (

)

key using the normal copying procedure.

Auto power shut-off mode

When the unit enters the auto power shut-off mode, the power

save (

) indicator will light up and other indicators except the

ONLINE indicator will go out. The auto power shut-off mode saves

more power than the preheat mode but requires a longer time

before starting copying. To copy from the auto power shut-off

mode, press the start (

) key. Then make desired copier selec-

tions and press the start (

) key using the normal copying proce-

dure.

Auto clear

The unit returns to the initial settings a preset amount of time after

the end of job.

This preset amount of time (auto clear time) can be changed.

Resolution of AUTO & MANUAL mode

You can set the copy resolution used for AUTO and MANUAL

(

) exposure mode.

2. Toner save mode (AR-203E/5420)

1) Press the exposure mode selector key to select the MANUAL

(

) mode.

2) Press and hold down the exposure mode selector key for

approximately 5 seconds. The MANUAL (

) indicator will

go out and the PHOTO (

) indicator will begin to blink. The

light and dark indicator marked "5" will light up, indicating the

standard toner mode is active.

3) To enter the toner save mode, press the light (

) key. The

light and dark indicator marked "1" will light up, indicating the

toner save mode is selected.

4) Press the exposure mode selector key. The PHOTO (

)

indicator will stop blinking and light up steadily. The light and

dark indicator marked "3" will light up. The toner save mode is

now active.

Note: To return to the standard mode, repeat the procedure but

use the dark (

) key to select exposure level "5" in step

3).

3. User programs (AR-203E/5420)

The user programs allow the parameters of certain functions to be

set, changed, or canceled as desired.

Set the power save modes, auto clear time, preheat mode,

SPF automatic original discharge time, resolution of AUTO &

MANUAL mode and reset factory setting.

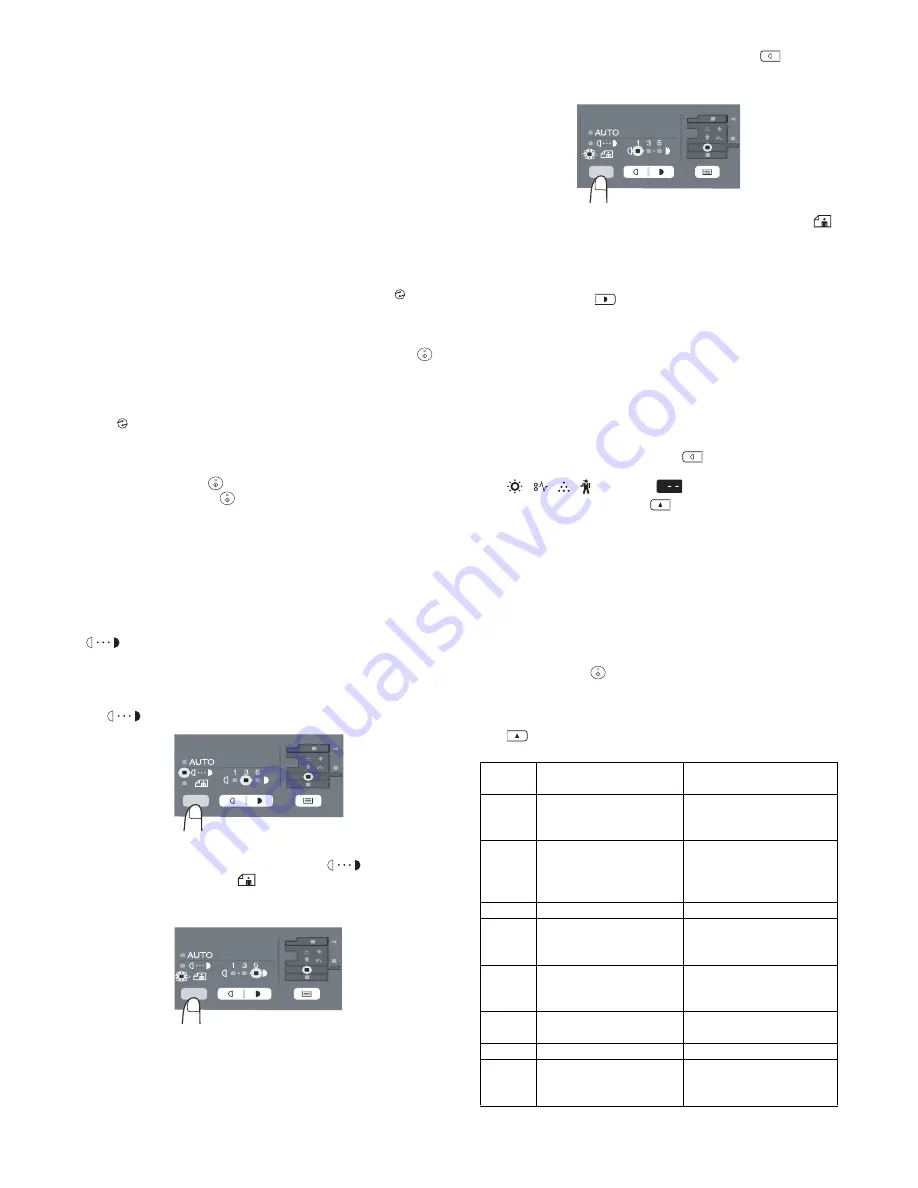

1) Press and hold down the light (

) key simultaneously for

more than 5 seconds until all the alarm indicators

(

,

,

,

) blink and "

" appears in the display.

2) Use the left copy quantity (

) key to select a user program

number (1: Auto clear time, 2: Preheat mode, 3: Auto power

shut off mode, 4: Auto power shut off timer, 6: SPF automatic

original discharge time, 10: Resolution of AUTO & MANUAL

mode, 21: Reset factory, 24: Prevention of OC copies when

the SPF is up function, 25: Copy effective paper width setting

function (Bypass tray), 26: Copy effective paper width setting

function (Tray), 28: Selection of copy start state (Polygon rota-

tion on/off), 29: Fusing temperature setting when the bypass

tray is used). The selected number will blink in the left side of

the display.

3) Press the start (

) key. The entered program number will be

steadily lit and the currently selected parameter number for the

program will blink on the right side of the display.

4) Select the desired parameter using the right copy quantity

(

) key. The entered parameter number will blink on the

right of the display.

Program

No.

Mode

Parameters

1

Auto clear time

1

→

10 sec., 2

→

30 sec.,

*3

→

60 sec., 4

→

90 sec.,

5

→

120 sec., 6

→

OFF

2

Preheat mode

*1

→

30 sec., 2

→

60 sec.,

3

→

5 min., 4

→

30 min.,

5

→

60 min., 6

→

120 min.,

7

→

240 min.

3

Auto power shut off mode

*1

→

ON, 2

→

OFF

4

Auto power shut off timer

*1

→

5 min., 2

→

30min.,

3

→

60 min., 4

→

120 min.,

5

→

240 min.

6

SPF automatic original

discharge time

1

→

5 min., *2

→

30 min.,

3

→

60 min., 4

→

120 min.,

5

→

240 min., 6

→

OFF

10

Resolution of AUTO &

MANUAL mode

*1

→

300dpi, 2

→

600dpi

21

Reset factory

1

→

YES, *2

→

NO

24

Prevention of OC copies

when the SPF is up

function

*1

→

ON, 2

→

OFF

Summary of Contents for AR-203E X

Page 172: ...Memo ...

Page 173: ...Memo ...