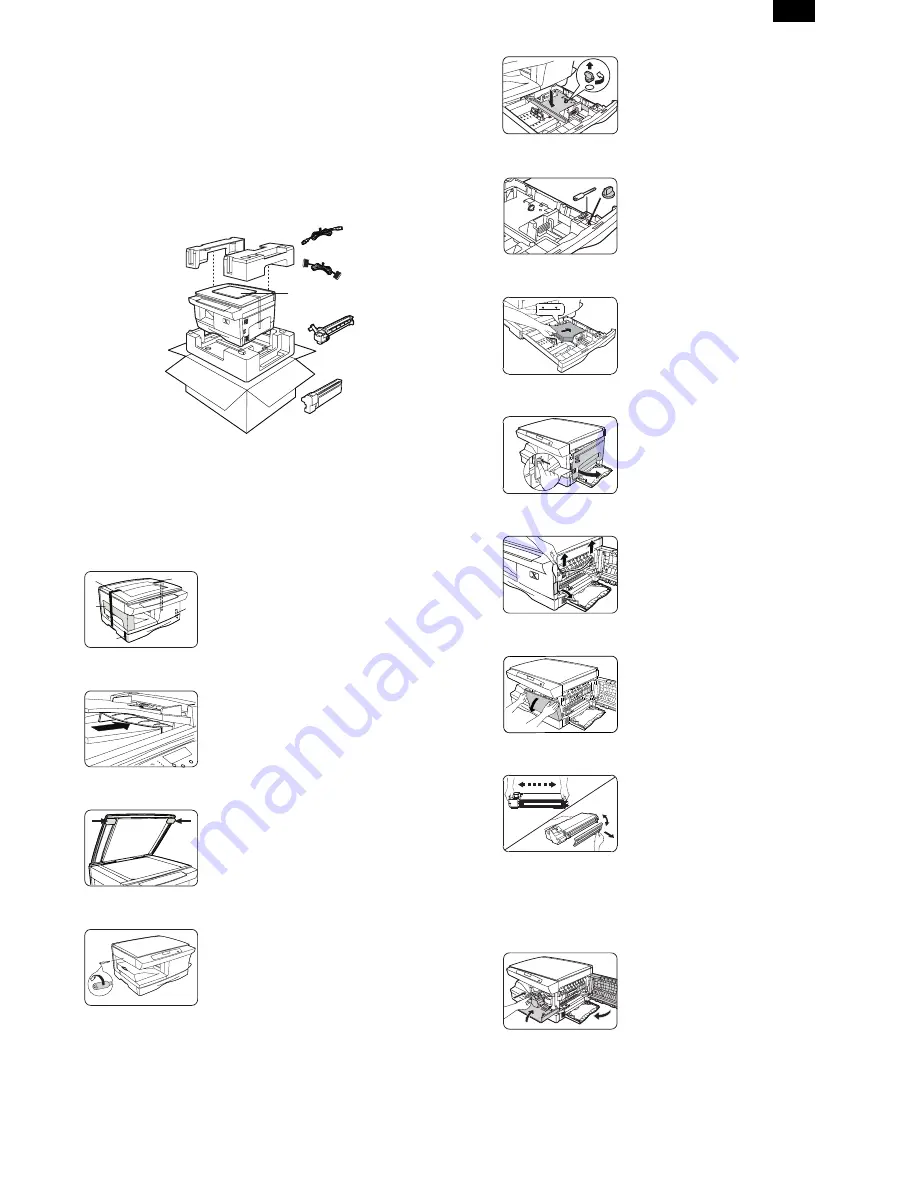

[4] UNPACKING AND INSTALLATION

1. CHECKING PACKED COMPONENTS

AND ACCESSORIES

As you unpack the WorkCentre, familiarize yourself with its contents.

After the WorkCentre is installed, and the Ready Indicator is lit, the

WorkCentre is ready to make copies.

IMPORTANT: Save the carton and packing materials. They should be

used to repack the WorkCentre if it has to be shipped

for servicing or in case you move.

∗

Note: To ensure reliability of the WorkCentre use the IEEE-1284

compliant parallel cable that is supplied with the machine. Only

cables labeled "IEEE-1284" can be used with your Work-

Centre.

2. Installation

Follow the steps below to properly set up your Xerox WorkCentre.

1) Remove the bag from the WorkCentre.

2) Remove the pieces of tape A, B, C,

D, and the packing material E.

XD155df copier only

Remove the tape and the packing material

supporting the clear plastic 2-sided tray.

XD155df copier only

To ensure the 2-sided tray is in the

correct position, gently push it in the

direction shown by the arrow.

3) Open the document cover and

remove the packing materials shown.

4) Unscrew and remove the shipping

screw from the left side of the

WorkCentre.

CAUTION: The WorkCentre will

malfunction if the shipping

screw is not removed.

5) Lift and pull open the paper tray.

Turn and remove the paper tray

button.

CAUTION: Paper will misfeed if the paper

tray button is not removed.

For the XD 120f/124f/155df copier only

Note: Be sure to remove the pressure

plate lock from both paper trays.

6) Secure the paper tray button and the

shipping screw in the locations shown.

●

Turn the paper tray button to secure

its storage position.

Note: Save the paper tray button and the

shipping screw. They will be

needed if the WorkCentre has to

be moved.

7) Load paper into the tray.

●

Refer to the Loading Paper section

for additional information.

●

Do not fill above the max line.

8) Push the paper tray firmly back into

the WorkCentre.

Note: Ensure that the alternate paper tray

is lowered (XD 104/124f/155df only).

9) Press the release lever to open the

side cover.

10) Remove the Caution tape from the

cover.

11) Remove the two red fuser pins by

pulling the string upward one at a

time.

●

Discard the fuser pins.

Note: Misfeeds will occur if the fuser pins

are not removed.

CAUTION: Ensure that the side cover is

always open before opening

the front cover.

12) Press the front cover release buttons

to open the front cover.

13) Remove the starter toner cartridge

from the silver bag. Vigorously shake

the cartridge to loosen the toner.

●

Thoroughly shaking the cartridge will

assure maximum copies per

cartridge.

●

Xerox has included a Starter Toner

Cartridge. Purchased replacement

toner cartridges will yield

approximately three times the number

of copies.

14) Remove the toner cartridge cover.

15) Slide the toner cartridge into the

WorkCentre until it locks into place.

16) Close the front cover and the side

cover.

Skip to the Printer Driver Software

Installation section in this User Guide to

set up the WorkCentre XD for printing.

Packing material

Power cord

IEEE-1284

Parallel Cable *

User documentation/

Installation CD

Drum cartridge

(installed in the

machine)

Starter toner

cartridge

A

D

C

E

B

1

2

1

2

3

AL-1550

4 – 1

Summary of Contents for AL-1550

Page 12: ... 10 ELECTRICAL SECTION 1 Block diagram A Overall block diagram AL 1550 10 1 ...

Page 13: ...B Main PWB block diagram AL 1550 10 2 ...

Page 16: ... 11 CIRCUIT DIAGRAM MCU 1 AL 1550 11 1 ...

Page 17: ...MCU 2 AL 1550 11 2 ...

Page 18: ...MCU 3 AL 1550 11 3 ...

Page 19: ...MCU 4 AL 1550 11 4 ...

Page 20: ...MCU 5 AL 1550 11 5 ...

Page 21: ...MCU 6 AL 1550 11 6 ...

Page 22: ...MCU 7 AL 1550 11 7 ...

Page 23: ...OPU AL 1550 11 8 ...

Page 24: ...ACTUAL WIRING DIAGRAM 1 AL 1550 11 9 ...

Page 25: ...ACTUAL WIRING DIAGRAM 2 DSPF UNIT AL 1550 11 10 ...