36U-S610

5

CIRCUIT PROTECTION

The receiver is protected by a 4.0A fuse (F701),

mounted on PWB-A, wired into one side of the AC

line input.

X-RADIATION PROTECTOR CIRCUIT TEST

After service has been performed on the horizontal

deflection system, high voltage system, B+ system,

test the X-Radiation protection circuit to ascertain

proper operation as follows:

1. Apply 120V AC using a variac transformer for accurate

input voltage.

2. Allow for warm up and adjust all customer controls

for normal picture and sound.

3. Receive a good local channel.

4. Connect a digital voltmeter to TP651 and make sure

that the voltmeter reads 13.2 ±0.7V.

5. Apply external 16.3V DC at TP651 by using an

external DC supply, TV must be shut off.

6. To reset the protector, unplug the AC cord and plug

the AC cord power on. Now make sure that normal

picture appears on the screen.

7. If the operation of the horizontal oscillator does not

stop in step 5, the circuit must be repaired before the

set is returned to the customer.

HIGH VOLTAGE CHECK

High voltage is not adjustable but must be checked

to verify that the receiver is operating within safe

and efficient design limitations as specified checks

should be as follows:

1. Connect an accurate high voltage meter between

ground and anode of picture tube.

2. Operate receiver for at least 15 minutes at 120V AC

line voltage, with a strong air signal or a properly tuned

in test signal.

3. Enter the service mode and select the service

adjustment "V18" and Bus data "01" (Y-mute on, CRT

Cut Off).

4. The voltage should be approximately 33.0kV (at zero

beam).

If a correct reading cannot be obtained, check circuitry

for malfunctioning components. After the voltage test,

make Y-mute off to the normal mode.

INSTALLATION AND SERVICE INSTRUCTIONS

Note:

(1) When performing any adjustments to resistor controls and transformers use non-metallic

screwdrivers or TV alignment tools.

(2) Before performing adjustments, the TV set must be on at least 15 minutes.

Summary of Contents for 36US50

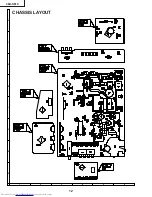

Page 12: ...36U S610 6 5 4 3 2 1 A B C D E F G H 12 CHASSIS LAYOUT ...

Page 13: ...36U S610 6 5 4 3 2 1 A B C D E F G H 13 BLOCK DIAGRAM ...

Page 15: ...36U S610 16 15 12 11 10 9 8 7 6 5 4 3 2 1 A B C D E F G H SCHEMATIC DIAGRAM MAIN 1 Unit ...

Page 16: ...12 11 10 9 8 7 6 5 4 3 2 1 A B C D E F G H SCHEMATIC DIAGRAM MAIN 2 Unit 36U S610 18 17 ...

Page 17: ...6 5 4 3 2 1 A B C D E F G H 19 SCHEMATIC DIAGRAM CRT Unit ...

Page 18: ...36U S610 21 20 12 11 10 9 8 7 6 5 4 3 2 1 A B C D E F G H SCHEMATIC DIAGRAM AV Unit ...

Page 19: ...36U S600 23 22 12 11 10 9 8 7 6 5 4 3 2 1 A B C D E F G H SCHEMATIC DIAGRAM P IN P Unit ...

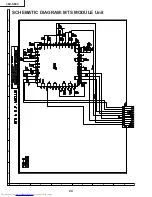

Page 20: ...36U S600 6 5 4 3 2 1 A B C D E F G H 24 SCHEMATIC DIAGRAM MTS MODULE Unit ...

Page 21: ...36U S610 6 5 4 3 2 1 A B C D E F G H 25 PWB A MAIN Unit Wiring Side ...

Page 22: ...36U S610 6 5 4 3 2 1 A B C D E F G H 26 PWB A MAIN Unit Chip Parts Side ...

Page 23: ...27 6 5 4 3 2 1 A B C D E F G H 36U S610 PWB B CRT Unit Wiring Side ...