7

7-1

7-2

14EM4RU

21EM4RU

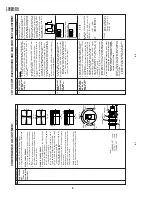

PIF ADJUSTMENT

No.

Adjusting point

Adjusting procedure/conditions

W

aveform and others

T

uner IFT

( PRESET )

1

1

.

Get the tuner ready to receive the CH. E - 9

signal,but with no signal input.

Adjust the PLL data.

2

.

Connect the sweep generator's output cable to

the tuner antenna. ( RF SWEEP )

3.

Adjust the sweep generator's to 80dBuV

.

4.

Connect the response lead ( use LOW IMPED-

ANCE probe with wave detector ; see Fig.1 ) to

the tuner's IF output terminal. (

This terminal

must have the probe alone connected ).

5

.

Set the RF

AGC to 0 - 6 V with no saturation with

the waveform.

6

.

Adjust the tuner IF coil to obtain the waveform as

shown in Fig. 2.

Note:

B

e

sure to keep the tuner cover in position

during this adjustment.

RF-AGC

T

AKE OVER

POINT AD-

JUSTMENT

(I

2

C BUS

CONTROL)

1.

Receive "P

AL

COLOUR BAR" signal.

»

Signal Strength: 57

±

1 dB

µ

V (75 ohm open)

2.

Connect the oscilloscope to

TP201(T

uner

’s

AGC

T

erminal) as shown in Fig. 3.

3

.

Call "AGC" mode in service mode.

Adjust the

"AGC" bus data to obtain the

T

uner output pin

drop 0.1V below maximum voltage.

4.

Change the antenna input signal to 63~67dB

µ

V,

and make sure there is no noise.

5

.

T

urn up the input signal to 90~95 dB

µ

V to be sure

that there is no cross modulation beat.

Note: For the 50 ohm signal

strength gauge, when not

using 50/75 impedance

adapter

, signal strength is

52

±

1dB

µ

V(75 ohm open), in-

stead of 57

±

1dB

µ

V (75 ohm

open).

Precaution: The loss of using

impedance adapter

2

Fig. 3

Fig.1

Fig.2

»

Bias bo

x:

About 4.5

V

Oscilloscope

0.1V

TV Set

Bias box

TP210

+

+

–

–

E-9 CH

P

C

10k

100k

1n60

75ohm

IF OUT

-1.5+/-0.8dB

1000p

Oscilloscope

ADJUSTMENT PRECAUTION:

Make sure

TV Set is in "Normal Condition" before switch to service mode for adjust-

ment.

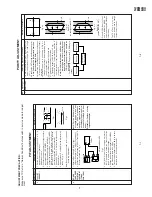

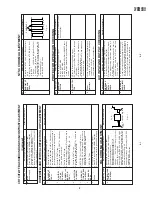

PURITY

ADJUSTMENT

No.

Adjusting point

Adjusting procedure/conditions

W

aveform and others

PURITY

ADJ.

1

.

Receive the GREEN-ONL

Y

signal.

Adjust the

beam current to about 500

µ

A (14") and 700

µ

A

(21").

2

.

Degauss the CR

T

enough with the degausing coil.

Note:

Follow the Job Instruction Sheet to ad-

just the magnetic field.

3.

Maintain the purity magnet at the zero magnetic

field and keep the static convergence roughly

adjusted.

4

.

Observe the points a, b as shown in Fig. 4-1

through the microscope.

Adjust the landing to the

rank A

requirements.

5.

Orient the raster rotation to 0 eastward.

6.

T

ighten up the deflection coil screws.

»

T

ightening torque: 108

±

20 N (1

1

±

2 kgf)

7

.

Make sure the CR

T

corners landing meet the

A

rank requirements. If not, stick the magnet sheet

to correct it.

Note:

This adjustment must be done after

warming up the unit for 30 minutes or

longer with a beam current over 500

µ

A.

(For 21" the beam current should be

over 500

µ

A.)

*

For the following colours press R/C RGB key to

change.

1

*

Press R/C RGB key for 1 sec-

ond in NORMAL MODE, the

colour will change to RGB mono

colour mode.

The

TEXT

Key "R. G. Cy" Key

can be directly use to change

to other colours screen.

a

b

A

B

A

B

A = B

A = B

Rank "A"

(on the right of the CRT)

Rank "A"

(on the left of the CRT)

Fig. 4-1

Fig. 4-2

Fig. 4-3

Green-only

Blue-only

Red-only

Signal-colour

screen cleared

Summary of Contents for 14EM4RU

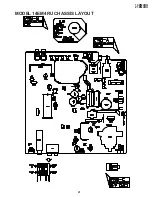

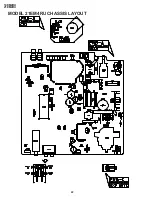

Page 21: ...21 14EM4RU 21EM4RU MODEL 14EM4RU CHASSIS LAYOUT ...

Page 22: ...22 14EM4RU 21EM4RU MODEL 21EM4RU CHASSIS LAYOUT ...

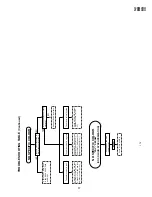

Page 24: ...24 14EM4RU 21EM4RU BLOCK DIAGRAM MAIN UNIT 14EM4RU ...

Page 25: ...25 14EM4RU 21EM4RU ...

Page 26: ...26 14EM4RU 21EM4RU BLOCK DIAGRAM MAIN UNIT 21EM4RU ...

Page 27: ...27 14EM4RU 21EM4RU ...

Page 28: ...28 14EM4RU 21EM4RU BLOCK DIAGRAM HEADPHONE UNIT BLOCK DIAGRAM ...

Page 31: ...31 14EM4RU 21EM4RU 10 11 12 13 14 15 16 17 18 19 ...

Page 32: ...32 14EM4RU 21EM4RU MAIN UNIT 21EM4RU A B C D E F G H I J 1 2 3 4 5 6 7 8 9 10 ...

Page 33: ...33 14EM4RU 21EM4RU 10 11 12 13 14 15 16 17 18 19 ...

Page 34: ...34 14EM4RU 21EM4RU A B C D E F G H I J 1 2 3 4 5 6 7 8 9 10 CRT UNIT 14EM4RU CRT UNIT 21EM4RU ...

Page 35: ...35 14EM4RU 21EM4RU A B C D E F G H I J 1 2 3 4 5 6 7 8 9 10 HEADPHONE UNIT ...

Page 37: ...37 14EM4RU 21EM4RU 10 11 12 13 14 15 16 17 18 19 ...

Page 38: ...38 14EM4RU 21EM4RU PWB A MAIN UNIT Chip Parts Side A B C D E F G H I J 1 2 3 4 5 6 7 8 9 10 ...

Page 39: ...39 14EM4RU 21EM4RU 10 11 12 13 14 15 16 17 18 19 ...

Page 49: ...49 14EM4RU 21EM4RU ...