97-610, 97-6152 • REV. 7/04

9

PRESSURE

W

ASHER

OPERA

T

OR’S MANU

AL

INSTALLATION

INSTALLATION

Place machine in a convenient location providing ample

support, drainage and room for maintenance (see page

6).

Location:

The location should protect the machine from damaging

environmental conditions, such as wind, rain and freez-

ing.

1. The machine should be run on a level surface

where it is not readily influenced by outside sources

such as strong winds, freezing temperatures, rain,

etc. The machine should be located considering

accessibility for the replacing of components and

the refilling of detergents, adjustments and main-

tenance. Normal precautions should be taken by

the operator of the machine to prevent excess

moisture from reaching the power unit or electri-

cal controls.

2. It is recommended that a partition be made be-

tween the wash area and the machine to prevent

direct spray from the spray gun from coming in

contact with the machine. Excess moisture reach-

ing the power unit or electrical controls will reduce

the machine’s life and may cause electrical shorts.

3. During installation of the machine, beware of poorly

ventilated locations or areas where exhaust fans

may cause an insufficient supply of oxygen. Suffi-

cient combustion can only be obtained when there

is a sufficient supply of oxygen available for the

amount of fuel being burned. If it is necessary to

install a machine in a poorly ventilated area, out-

side fresh air may have to be piped to the burner

and a fan installed to bring the air into the area.

4. Do not locate near any combustible material. Keep

all flammable material at least 20 feet away.

Allow enough space for servicing the machine.

Local code will require certain distances from floor

and walls. (Two feet away should be adequate).

WARNING: Avoid small areas or near exhaust fans.

Gas Codes:

Confer with local gas company and with proper mu-

nicipal officials regarding any specific code or regula-

tions governing the installation. The installation must

conform to local codes.

Electrical:

The machine, when installed, must be electrically

grounded in accordance to local codes. Check for

proper power supply using a volt meter; check the se-

rial plate for the correct requirements.

Gas Piping:

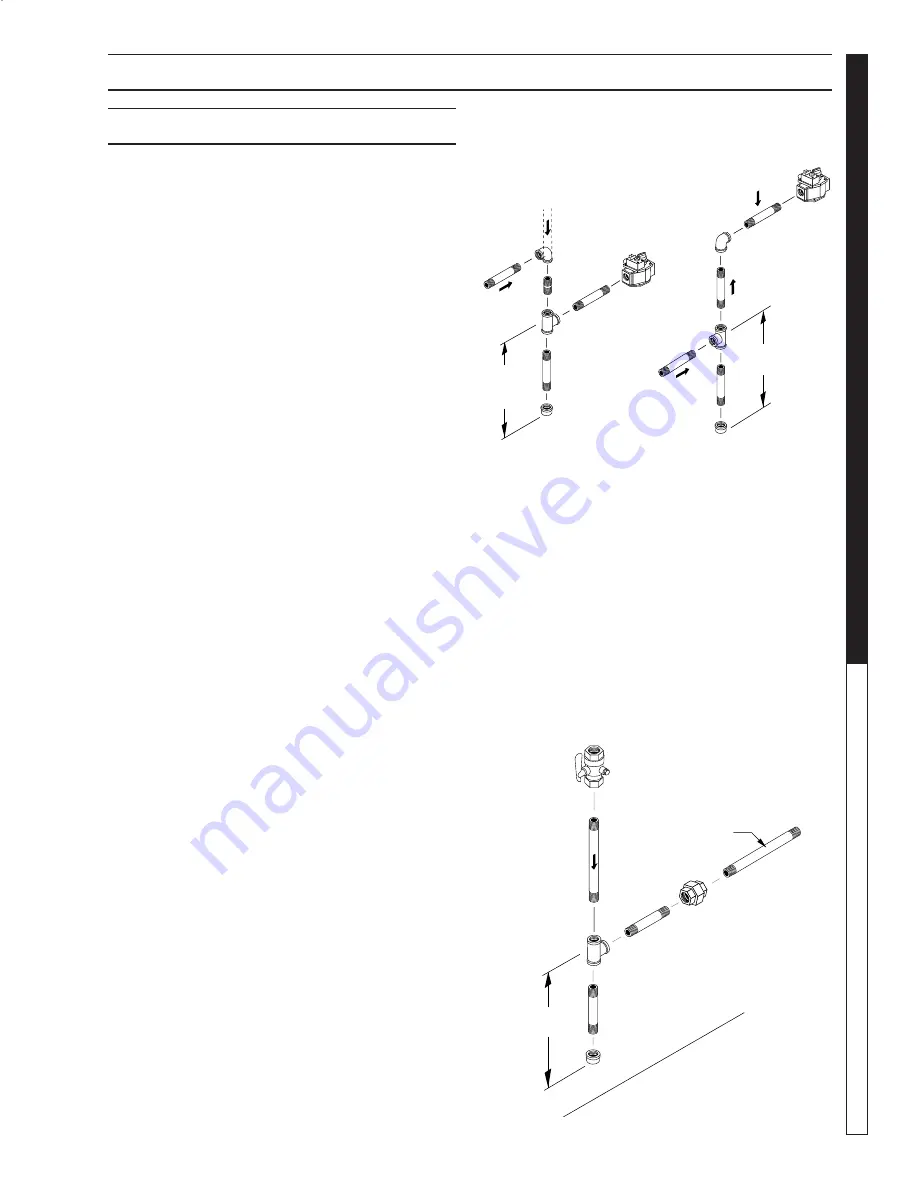

Figure 1: DRIP LEG

Sediment trap (drip leg) must be

installed in the supply line.

Install a union in the gas line adjacent to and upstream

from the control manifold and downstream from the

manual main shut-off valve. A 1/8" NPT plugged tap-

ping accessible for test gauge connection shall be in-

stalled immediately upstream of the gas supply con-

nection for the purpose of determining the gas supply

pressure to the burner, and to prevent damage to gas

valve.

If a manual gas shut off valve is not in the gas supply

line within six feet of the machine and in an accessible

location, one shall be installed.

Figure 2: UNION LOCATION

Manual

Shut-Off Valve

1/8" NPT Plugged

Pressure Gauge

Port Location

Union

Control Manifold

Tee

Flow

3" (7.62 mm)

Minimum

Floor Level

Pipe

Cap

To

Gas Valve

1/4" Test Port

(6" - 14 W.C.

or 1/2" PSIG)

Gas

Valve

Gas

Valve

Drop

3" (7.62 mm)

Minimum

3"

(7.62 mm)

Minimum