25/11/2019

LEAK INDICATING UNIT

LAE 3-8

- 11 -

5. Mounting the System

5.1 Basic Instructions

- Prior to commencing work, the documentation must be read and

understood. In case of ambiguities, refer to the manufacturer.

- The safety instructions in this documentation must be adhered to.

- Only qualified service companies may be used for mounting and

commissioning

1

.

- Leadthroughs for connection lines through which the explosion

atmosphere can carry over must be sealed gas-tight.

- Comply with relevant regulations regarding electric installation, ex-

plosion protection (e.g. EN 60 079-14, -17), and accident preven-

tion.

5.2 Mounting the Indicating Unit

- Wall mounting usually with dowels and screws in a dry room

-

NOT in potentially explosive areas.

- For housing dimensions and hole pattern, see Chap. 7.

5.3 Electrical Cables

Mains connection LAE and power supply for VLX .. A-Ex tool (5-wire):

- 1.5 mm

2

without ferrule or with ferrule without plastic collar

Potential-free relay contacts (6-wire):

- 1.5 mm

2

without ferrule or with ferrule without plastic collar

- 0.75 mm

2

with ferrule and plastic collar or with ferrule without plastic

collar

External signal (2-wire):

- 1.5 mm

2

without ferrule or with ferrule without plastic collar

- 0.75 mm

2

with ferrule and plastic collar or with ferrule without plastic

collar

Must be resistant to stored/pumped liquids

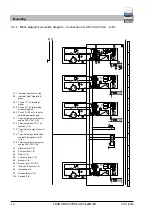

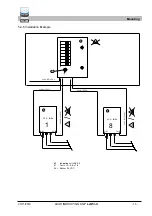

5.4 Electrical Wiring Diagram

(1) Install the electrical connection securely, without plug or switch-

ing connections.

(2) Observe the requirements for electric installations, if necessary,

also those of the electric companies.

(3) Terminal layout: (see also block diagrams in Chap. 5.4.3 and

5.4.4)

1

For Germany: Specialist service companies per Water Law that have documented qualifications to install

leak detection systems.

Mounting