MOVITRAC

®

31.. – FRS 31

15

Parameters

4

P 611 to 617

Binary outputs

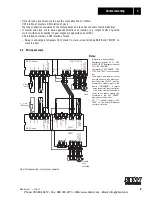

The programmable binary outputs on terminals 62/63/64 can be allocated the following signals in

addition to the usual signal types:

• “FRS alert signal” (see P 550)

active low

• “FRS lag error” (see P 551)

active low

• “Slave in position” (see P 554 and P 556) active high

• “Zero speed”

active high

P 760

Synchronous Operation

Yes / No

(only with FRS 31A option package)

Setting (when unit disabled):

• on slave with FRS 31 option package:

set synchronous operation = “YES”

• on master with FEN 31 option pcb:

synchronous operation = “NO” and speed control (P 770) = “NO”:

normal V/f mode

synchronous operation = “NO” and speed control (P 770) = “YES”:

speed control mode

P 761

MOVITRAC

®

is master/slave

TThis parameter determines the role of the appropriate unit/drive. Terminals 98 to 101 of the unit

defined as the “SLAVE” must receive pulses from the pulse output on terminals 81 to 84 of the

master. The appropriate wiring must be taken into account (see terminal connection diagram and

application examples). Setting a unit as the “SLAVE” will automatically activate speed control

(P 770).

P 762

Gear ratio factor master

Value range = 1...3.999.999.999

P 763

Gear ratio factor slave

These two parameters determine the angular velocity ratio of the slave to the master.

The following factors for master and slave drives must be taken into account during the calcula-

tion:

• exact gear ratios. To just two decimal places in the SEW catalog.

• input transmission ratios

• pulley diameter (including twice the belt thickness)

The

ratio between P 763 / P 762

is therefore calculated as:

• In cases of the

same type of synchronized drives

with identical gear ratios (including input

transmission), the value of both parameters will be “1”.

• If the ratio between P 762 and P 763

with the same type of drive

is # 1, proportional operation

with an appropriate ratio can be selected. Examples:

P 763 = 101 / P 762 = 100

→

slave drive runs 1.01 times faster than the master.

P 763 = 5 / P 762 = 10

→

slave drive runs half as fast as the master.

P 763 = 4444 / P 762 = 2000

→

slave drive runs at 2.222 times the speed of the master.

• Where the

drives are of different types

(example: main drive and feed drive for flying saws), the

desired angular velocity ratio can be specified.

P 763

=

(i

gear

• i

input transmission

) slave • pulley diam

master

P 762

(i

gear

• i

input transmission

) slave • pulley diam

slave

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]