Multi-layer diaphragm pump

Serie 409.2 ML

Operating instruction

18

www.sera-web.com

Technical modifications reserved!

TA 431

Rev.

8 en

06/2015

7.3.6

Maintenance of the drive motor

The electric motor should always be kept clean so that neither

dust, dirt, oil nor other contaminates may affect the correct op-

eration.

In addition, we recommend to ensure that:

•

the motor does not produce strong vibrations

•

suction and blowing openings for the supply of cooling air

are not closed or restricted (may lead to unnecessary

high temperatures in the windings).

The ball bearings inserted in the motor are lubricated for life.

7.3.7

Restart

Restart the system as described in Chapter 7.3.4 after mainte-

nance work of after longer periods of standstill.

8

Installation

CAUTION!

In case of operation in explosion-hazardous areas, the

instructions in Chapter 9 must also be followed!

8.1

Installation instructions

•

The standard model of the pump is only approved for in-

stallation in dry rooms in a non-aggressive atmosphere,

at temperatures b2°C and +40°C and at permit-

ted humidity until approx. 90%, altitude 1000 m above

sea level. (For operation in explosion-harzardous areas,

see Chapter 9).

•

For dimensions of the pump connections and fixing holes,

see Fig. 04, Table 02.

•

Install the pump in such a way that there is no vibration

and no tension and that it is aligned precisely.

•

Install the pump at the optimum possible operating height.

Mount the pump in such a way that the valves are verti-

cal.

•

Ensure that there is sufficient space around the pump

body and the suction and pressure valve so that these

parts may be easily dismantled, if required.

•

The stroke length adjustment, indicator scale and visual

diaphragm rupture signalling must be easily accessible

and readable.

•

Design the nominal diameters of the downstream pipes

and of the connections built into the system to be the

same size or larger than the inlet / outlet nominal widths

of the pump valves.

•

To check the pressure ratios in the pipe system, we rec-

ommend to provide for connections for pressure gauges

(e.g. manometers) near the suction and pressure attach-

ments.

•

Provide evacuation fittings

•

Prior to connecting the pipes, remove the plastic caps on

the suction and pressure attachments of the pump.

•

Check that the fixing screws for the pump body are tightly

fitted and, if necessary, retighten.

Torque for tightening the fixing screws

Pump body

without

mounting plate

15 NM

Pump body

with

mounting plate

15 NM

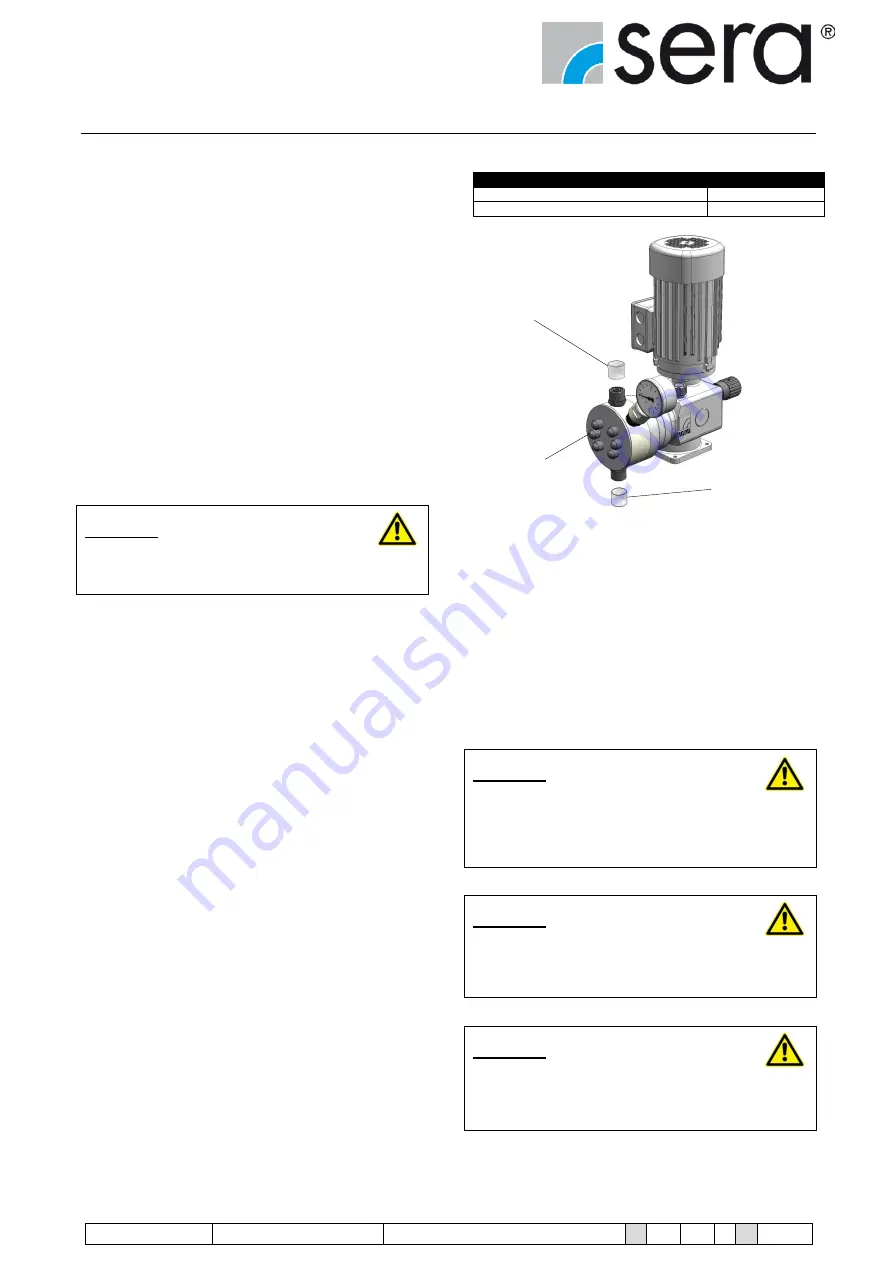

Plastic cap

Fixing screws

Plastic cap

Fig. 19 Multi-layer diaphragm pump with plastic caps

•

For models with a built-on actuator, ensure sufficient

space for removal of the cover

(see Chapter 6.1 “Dimensions“)

•

Connect pipes to the pump in such a way that there are

no forces acting on the pump, such as e.g. misalignment,

weight or stress of the pipe.

•

Keep the suction lines as short as possible.

•

Use pressure- and medium-resistant hoses / pipes.

•

All pipes and containers connected to the pump must

comply with the regulations and must be cleaned, ten-

sion-free and intact.

CAUTION!

Where toxic, crystal-forming or corrosive liquids are being

delivered, the pipe system must have equipment to enable

it to be emptied, cleaned and, if necessary, rinsed with a

suitable medium.

CAUTION!

In the case of operation on the 60Hz network it is essential

to consider the possible higher stroke frequency when

designing the pipe geometry.

CAUTION!

The multi-layer diaphragm pump must be installed in such

a way that no damage can be caused if the medium leaks

out.