MA-5950_EN.doc

Page 3 on 15

Rev: 29-03-19

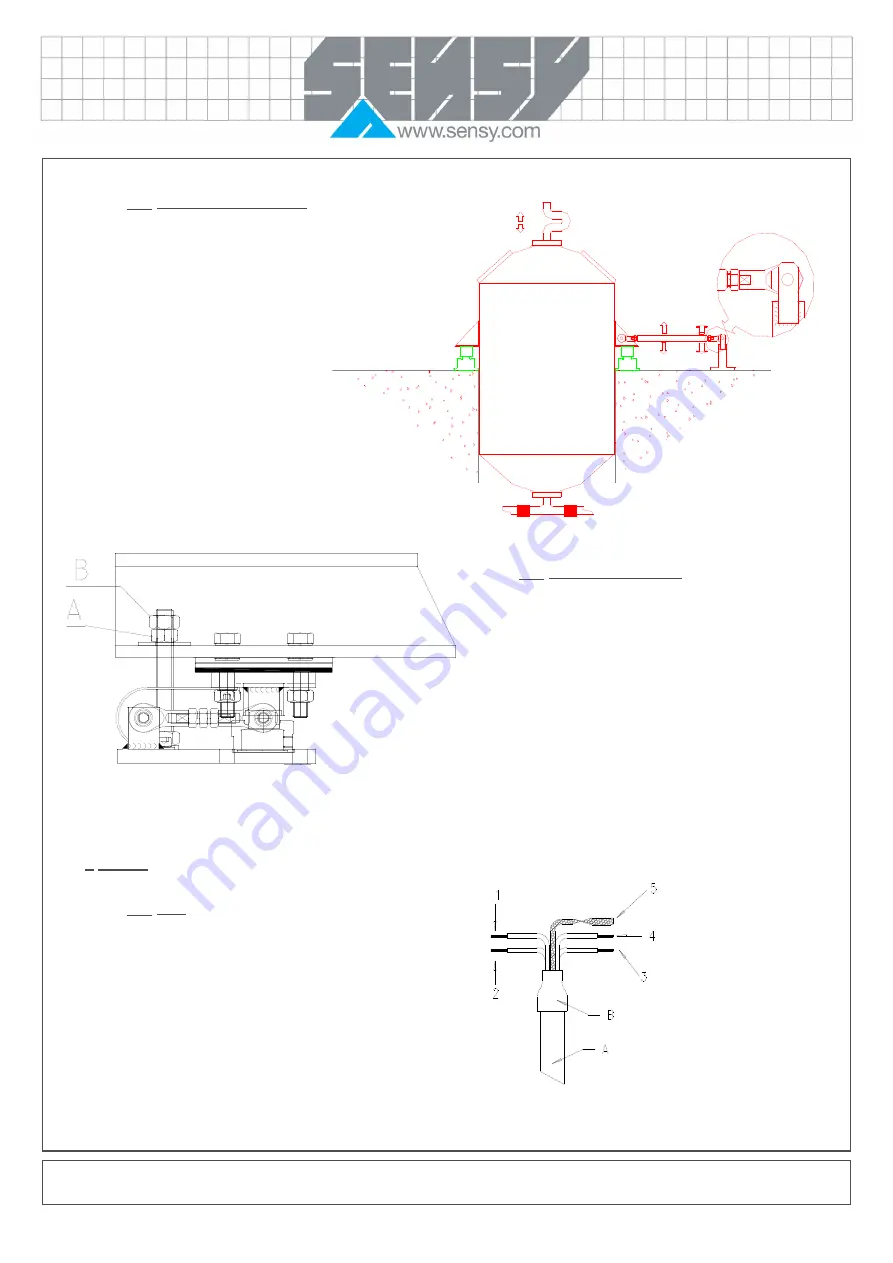

1.5.

Exterior mechanical influences

In order to avoid measurement errors, the load to be

weighed must not be subject to parasitic contributions: if

there are any connecting pipes, cables and balls or draw-

bolts, they must be installed with THE GREATEST

FLEXIBILITY. Also, ladders or bridges for access will be

suitably articulated (clamping).

1.6.

Setting of the counter force

This setting has to be done whilst the sensor is UNLOADED.

By hand, bring the nut 1 mm away from the structure, then screw B

to A.

Finally, using a key, block A onto B so as not to exert any effort on

the sensor.

2.

CABLING

2.1.

Cable

The cells are delivered with a 4-wire screened cable.

The screen (shielded cable) cannot in any case be in contact with the

ground, e.g.; in metallic junction boxes, it is necessary to isolate the screen

with a sheath (thermal).

The screen can only be connected to standardized earth.

It is advised to install a thermo-retractable sheath (retracted 4x) at the end of

the cable inside a waterproof paste, in order to avoid any leak. If there is any

possible danger of damage along its wiring, it is necessary to use an

additional cable protection, passing the cable through a pipe (steel,

preferably).

COLOR CODE

1) Excitation- (Yellow)

2) Exc (Brown)

3) (Green)

4) Signal- (White)

5) Screen

A) Cable PVC

B) Thermo-retractable

sheath