21

7.

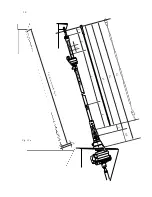

Tighten the screw

lightly.

Adjust the line guide vertically so that it is mid-

way between the line drum flanges. If the casing

or line guard come into contact with the line drum

flanges, unnecessary friction will be caused.

8.

Adjust the alignment of the line guide towards

the first lead block and tighten screw. (See also

"Furling line arrangement"

, chapter 6.3. in

"Manual Furlex"

Push the locking block in until it rests against

the lower bearing assembly. Fasten the line

guide fitting in the line guard and bring this up

into the assembly position. Tighten the screws

in the stainless steel housing.

5.

1

2

2

=

=

Fig. 4.3.g

Fig. 4.3.f

Fig. 4.3.e

3

Summary of Contents for Furlex 200 TD

Page 23: ...23 Notes Comments...