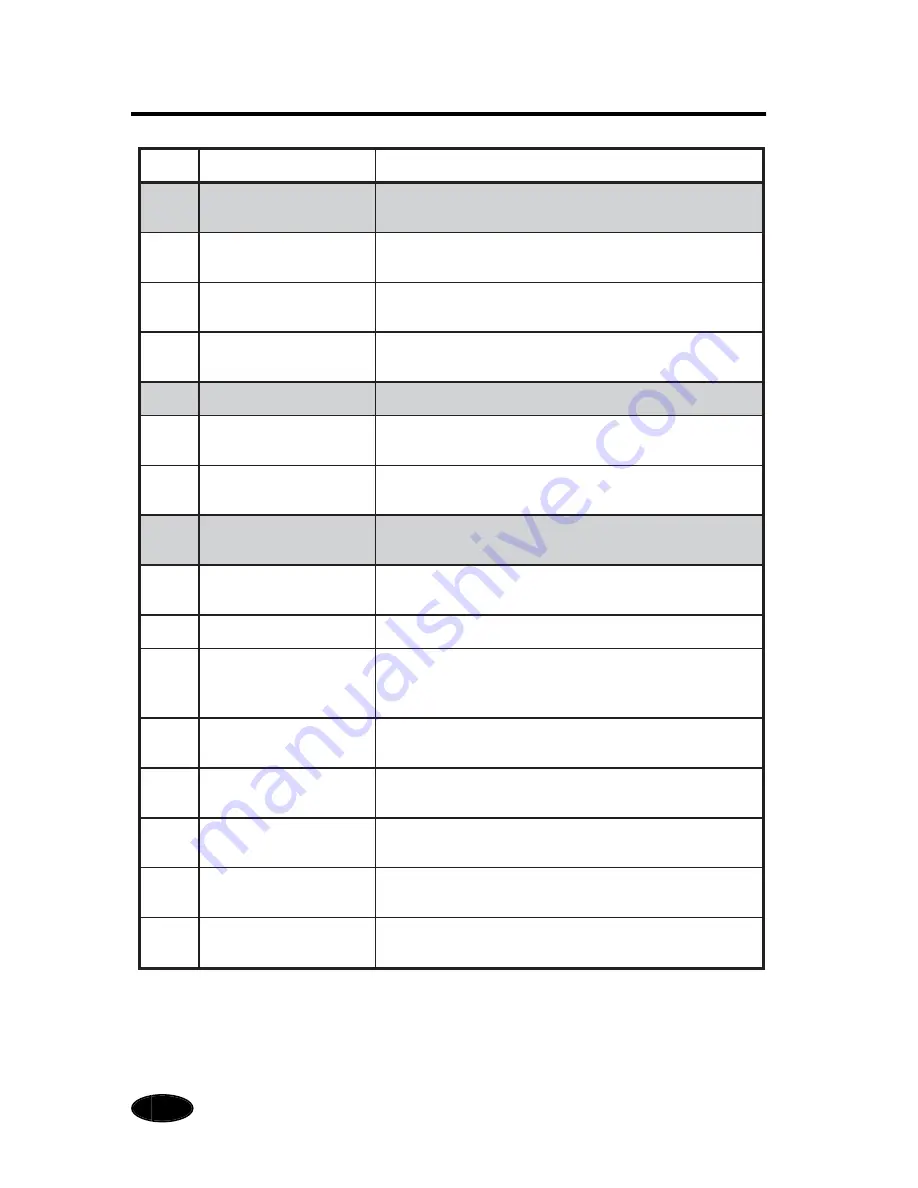

2

No.

Name

Description

1

Partition Cloth

The cloth that partitions the front of the dryer from the

external air to increase drying efficiency.

1-1

Partition Cloth

Attachment Hook

The metallic fitting that attaches the partition cloth to

the front of the printer.

1-2

Partition Cloth Bar

(Front)

The bar that attaches the partition cloth to the front of

the printer.

1-3

Partition Cloth

The bar that attaches the partition cloth to the bottom of

the printer.

2

Drying Guide Plate

The media path guide plate for using the dryer.

2-1

Drying Guide

Attachment Plate

The attachment plate that fits the drying guide plate to

the winding unit.

2-2

Drying Guide Sliding

Rail

Slide the drying guide plate upward to set the media to

the winding unit.

3

Dryer

The heater is builtin and the dryer sends warm wind by

fans to dry up the printed media.

3-1

Operation Panel

The operation panel for the dryer.

For details, see Chapter 3 Using the Operation Panel.

3-2

Breaker Switch

The switch that turns ON/OFF the dryer power.

3-3

Power Cord

The power cord that supplies power to the dryer.

The one end is secured to the dryer. Specification: 207

to 253 VAC, 50 Hz ± 1 Hz

3-4

Handle

The handle used for moving the dryer.

The handles are attached to both sides of the dryer.

3-5

Upper fans

The fans that are attached to blow air to the heater for

generating warm air.(Suction type)

3-6

Lower fans

The fans that circulate warm air into the dryer.

(Suction type)

3-7

Casters

The casters used for moving the dryer.

The caster has a lock and release function.

3-8

Exhaust Attachments

Attaching Part

The part to which the exhaust attachments (option) are

attached.