MOBILEMAX ASSEMBLY MANUAL

|

5

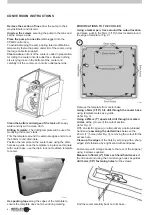

CONVERSION INSTRUCTIONS

REMOVAL INSTRUCTIONS

WARNING: ELECTRICAL WORK MUST ALWAYS BE

CARRIED OUT BY A QUALIFIED ELECTRICAL WORKER

Ensure that the cooler cannot be turned on

whilst

work is being carried out.

Remove all pads

(side panels) from cooler and put them

safely aside allowing access to the inside of the cooler.

ILL725-A

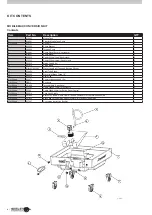

PACKING LIST

This kit contains the following components:

•

a 100 litre tank with wheels fitted,

•

a floating platform for the pump, with pump bracket

fitted.

• a replacement hose assembly

• cord storage hooks, cord restraint glands and

fasteners,

• a grille outlet and a grille frame and fasteners

• pop rivets and fasteners.

• cable ties.

• 1/2” brass nipple and lock nut.

•

Mains lead 3 pin 13 amp x 6m (fit plug to suit

location)

•

Communications Lead 6 Pin 1.5m CPMD to Switch

Plate Control

• Cable Gland 20mm to seal the 1.5m communications

lead hole drilled in the cooler

•

Enclosure, Cable Glands 16mm, Terminal Strip and

mounting screws for connection of field wiring mains

power to an IEC plugged cable to fit into the CPMD.

• Drilling and cutout Template

Unpack the kit to ensure it contains the above

components.

Additional items required to assemble the kit include;

• an electric drill,

• an electric jig saw or alternatively a narrow bladed

hand saw,

• a sharp knife,

• a philips head screwdriver,

• a pop-rivet gun,

• sandpaper,

• a tape measure, ruler and marker pen.

• a vacuum cleaner,

• a bucket of soapy water and clean loth,

• masking or packing tape,

•

20mm (3/4”) spade drill bit

•

25mm (1”) spade drill bit

•

16mm (5/8”) spade drill bit (Australia, South Africa

and Europe)

•

3mm (1/8”) drill bit

•

5mm (3/16”) drill bit

•

Teflon tape or approved sealing compound.

• scissors or a sharp blade knife,

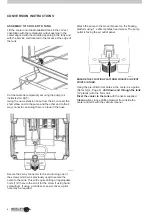

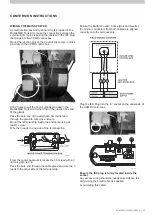

MODIFYING THE COOLER

The cooler requires some modification prior to fitting to

the MobileMAX Tank.

Some components will be removed and set aside for

later fitment to the MobileMAX Tank while others will be

discarded.

Remove packaged components located in the fan area

and set aside for later use.

Remove the float valve

by undoing the threaded in-line

connector.

Set the float assembly aside for later use.

Remove the plastic washer and “O”ring from inline

connector.

Discard the plastic inline connector only.

Summary of Contents for MobileMAX Series

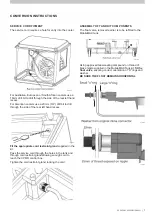

Page 15: ...DRILLING TEMPLATE INFORMATION ...