4

|

859731-D

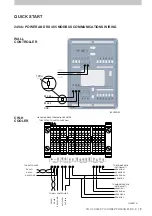

RS 485 MODBUS COOLER NODE ADDRESS

Screen Layout

ILL3632-B

RS 485 MODBUS NETWORK SETUP - FIRST TIME USE

IMPORTANT

- This Climate Wizard Wall Controller can control up to 15 CW-H coolers. Ensure

each cooler is powered up and has a unique node address set. Refer to installation literature

provided with the cooler for setup instructions.

Enter SETTINGS – CONFIGURATION – NETWORK menu

ILL3633-C

ILL3633-B

List shows all detected coolers.

Press SAVE to commit detected coolers to Wall Control memory.

QUICK START

ILL3632-A

INTERNAL

TEMPERATURE /

HUMIDITY

TIME

ON - OFF

COOL MODE

VENT MODE

PROGRAM MODE

SETTINGS

DATE

DATE

TIME

ON OFF

COOL MODE

VENT MODE

INTERNAL

TEMPERATURE /

HUMIDITY

PROGRAM MODE

SETTINGS

Summary of Contents for CW-H 2020 PLC

Page 1: ...OWNER S MANUAL CW H 2020 PLC WALL CONTROLLER English Original English Instructions ILL2468 A ...

Page 2: ......

Page 30: ...28 859731 D ...

Page 31: ......