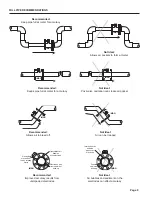

Tightening Flange Bolts

NOTE: Mating pipe flanges must be ANSI 150# full face (FF)

and/or raised face (RF).

1. Tighten flange bolts in an alternating pattern.

•

Tighten left flange bolt-1 to 20% recommended

torque.

•

Tighten right flange bolt-1 to 20% of

recommended torque.

•

Repeat steps a and b for each bolt in an

alternating order, such as shown at right,

tightening to 40%, then 60%, then 80%, and then

100%.

2. Test for leaks.

3. If needed, tighten further in 10% increments until

leaking stops.

DO NOT over-tighten. Over-tightening

can cause serious damage to the flow meter.

4. Recheck after 24 hours, adjusting if needed.

Suggested Tightening Sequence

Caution: Improper tightening sequence

can cause serious damage to the flow

meter.

• Do not tighten one side at a time.

• Do not tighten each bolt completely at

one time.

Santoprene Liner

Pipe Size

ft-lb

Nm

3”

25

34

4”

20

27

6”

42

57

8”

65

88

10”

73

99

12”

97

132

SUGGESTED FLANGE BOLT TORQUE

1

2

3

4

5

6

7

8

INSTALLATION and GROUNDING

Equalization and Grounding

Metal Pipe Installations.

To equalize the electrical potential

of the fluid, the iMAG meter, and the surrounding pipe, secure

the flange plates (factory-installed on the equalization wire)

to both pipe flanges at one of the bolt holes, as shown below.

Be sure the lock washer fits between the pipe flange and the

flange plate. For the best electrical bonding, remove rust

and paint to expose clean, bare metal where the equalization

flange plate lock washer contacts the pipe flange. Connection

must be inspected periodically for corrosion to maintain the

necessary low resistance connection.

Plastic Pipe Installations.

When the iMAG is installed in a

plastic piping system, grounding rings are recommended

(except 3” pipe size), especially in the presence of electrical

interference sources such as VFD pump drives. As shown in

the diagram below, the equalization wires should then be

connected to the grounding ring tabs instead of the flange

bolts as in metal piping installations. Where lightning is a

threat, or in severe electrical environments, an optional

connection to a nearby equipment ground or ground rod may

be advisable.

WARNING: ELECTRICAL SHOCK HAZARD

When the iMAG is installed in a plastic

piping system, or when externally powered,

the piping system must be grounded to meet

national and local electrical safety codes.

Failure to do so can result in electrocution.

Equalization Lug

Meter

Flange

Pipe

Flange

Gasket

Pipe Flange

Flange Plate

Lockwasher

Metal Pipe

Metal Pipe

Meter Flange

Gaskets

Equalization Lug

Ground Clamp

(Exothermically weld when

corrosion is a concern)

8’ Ground Rod

Earth

Grounding Ring

Gaskets

Grounding Ring

Gaskets

#6, #8, or #12 AWG Stranded

Copper Ground Wire < 5’

Plastic

Pipe

Plastic

Pipe

Grounding Ring Part Numbers:

4” = 100876 10” = 100879

6” = 100877 12” = 103288

8” = 100878

Page 7

Summary of Contents for iMAG

Page 19: ...Page 17 NOTES...