PROBLEM

PROBABLE CAUSES

Try…

Blank Display

Faulty wiring from power source to

meter or faulty AC power supply

Check for miswiring. Measure voltage with DMM

where red and black wires connect to terminal

block TB2 inside meter display head. Verify cor-

rect polarity and confirm that voltage is steady and

between 9Vdc and 32Vdc

Flow rate reads zero continuously

regardless of flow

Flow is below cutoff

Increase flow above cutoff

Flow rate shows [-] negative flow

and FWD total remains at [0] zero,

when flow is greater than cutoff

Meter is installed backwards

Reinstall correctly

Flow rate reading fluctuates ex-

cessively when flow is unchang-

ing

Excessively turbulent or unsteady

flow due to partially closed valves

or other flow obstructions

Pipe not full.

Pulsing flow due to combining mul-

tiple upstream flow sources

Insufficient mixing of upstream

chemicals

Low fluid conductivity < 20 µS/cm

Noisy electrical environment

Defective or noisy ac switching

power supply

Eliminate or minimize causes of flow disturbances

or increase meter damping

Provide back pressure or other means to ensure

pipe is filled

Move connection point further upstream

Move chemical injection downstream from meter

Replace with different type of meter

Improve grounding at meter and nearby potential

ly noisy electrical equipment. Increase distance

between meter and electrical noise sources.

Replace power supply

Flow Rate appears correct but

pulse/ frequency output is low,

erratic or absent

Wiring incorrect

External device input impedance

too low

Cable too long

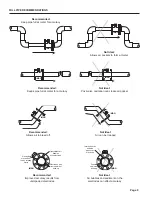

Compare wiring with appropriate wiring recom-

mendations

Use sourcing rather than sinking interface connec-

tion

Reduce interface pull-up resistance

Flow Rate appears correct but

pulse/frequency output is erratic

and/or too high

Electrical noise sources interfering

with pulse frequency signal

Wrong type of cable

Grounding problem

Isolate, remove or reduce noise sources. Move

meter control cable away from noise sources.

Use only twisted pair cable and ensure both signal

wires are on same twisted pair

Improve or try different grounding method.

Flow rate reads “COMM FAIL”

instead of rate

Cable between flow sensor body

and display head is disconnected,

miswired or damaged

Inspect cable for damage. Check cable connection

inside display head for correct wiring to five-posi-

tion connector, ensure that connector is properly

inserted, inspect for broken connections.

Page 17

NOTES

Summary of Contents for iMAG

Page 19: ...Page 17 NOTES...