3.1. Air Supply

3.1.1. Ensure the polisher air control valve (or throttle) is in the "Off" position before connecting to the air supply.

3.1.2. You will require an air pressure of 90psi, and an air flow according to the specification above.

3.1.3.

p

WARNING!

Ensure the air supply is clean and does not exceed 90psi while operating the polisher.

Too high an air pressure and/or unclean air will shorten the product life due to excessive wear, and may

be dangerous, causing damage and/or personal injury.

3.1.4. Drain the air tank daily. Water in the air line will damage the polisher

and will invalidate your warranty.

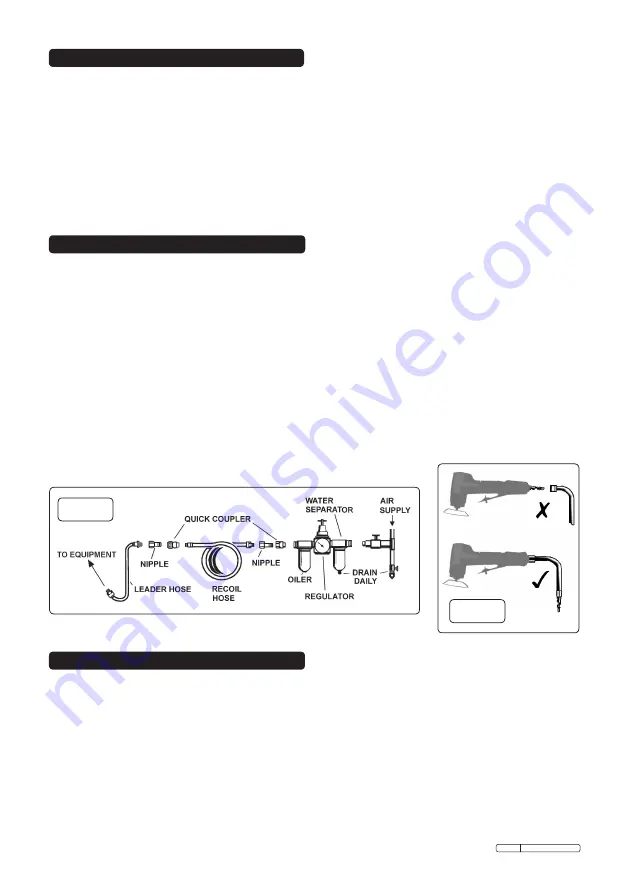

3.1.5. Clean air inlet filter weekly. Recommended hook-up procedure is shown in fig.2.

3.1.6. Line pressure should be increased to compensate for unusually long air hoses (over 8 metres).

The minimum hose diameter should be 1/4” I.D. and fittings must have the same inside dimensions.

3.1.7. Keep hose away from heat, oil and sharp edges. Check hoses for wear and make certain that all

connections are secure.

3.2. Couplings

3.2.1 Vibration may cause failure if a quick change coupling is connected directly to the air polisher.

To overcome this, connect a leader hose to the polisher. A quick change coupling may then be used to

connect the leader hose to the air line recoil hose. See figs.2 & 3.

p

WARNING! Ensure you read, understand and apply the safety instructions in Section 1 before use.

4.1. Assembly

4.1.1. Screw the backing pad into the polisher spindle, then tighten with supplied spanner. Apply the polishing

disc, use only discs with speed ratings equal to or higher than the speed rating of the polisher.

DO NOT

use cloth backed polishing discs.

4.1.2. Connect air supply to polisher, slide the safety catch (fig.1.1) and press the control valve lever (fig.1.2) to

check that the polisher is working correctly.

4.1.3. The air flow may be regulated by adjusting the regulator valve in the back of the handle.

4.2. Operating

4.2.1. The polisher is designed to provide a combined “rotary” and “random orbit” action.

4.2.2.

Always use a polish appropriate for the job.

Composite handle with rear exhaust reduces effects of

chill and noise level. Air motor with quality bearings for

smooth and powerful operation. Fitted with safety

trigger to prevent inadvertent operation. Integral gear

system reduces output speed, while maintaining a high

torque level. Supplied with hook-and-loop pad for use

with buffing and polishing heads - for full range see

pages 650 & 651 of your Sealey catalogue. Ø50mm

Hook-and-loop pad available separately (order Model

No. PTC50VA).

Pad Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ø75mm

Motor Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.5hp

Free Speed . . . . . . . . . . . . . . . . . . . . . . . . . . 2600rpm

Operating Pressure . . . . . . . . . . . . . . . . . . . . . . . 90psi

Air Consumption . . . . . . . . . . . . . . . . . . . . . . . . . 4cfm

Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/4”BSP

Noise Power . . . . . . . . . . . . . . . . . . . . . . . . . . . 94dB.A

Noise Pressure. . . . . . . . . . . . . . . . . . . . . . . . . 83dB.A

Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.41m/s²

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.08kg

3. PREPARING TOOL FOR USE

4. OPERATING INSTRUCTIONS

2. INTRODUCTION & SPECIFICATION

Original Language Version

SA704 Issue: 1 - 12/10/11

fig.2

fig.3