Function

18

02|NSE-M plus 138 |en

Function

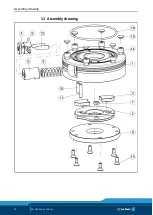

The item numbers to the corresponding individual parts refer to

the drawing in chapter 11.

The clamping system has a release mechanism with manual

actuation.

The actuating piston, which is actuated with a hexagon

screwdriver (angled pin wrench), can be accessed on the side of

the base body of the quick change pallet module.

A cam on the drive piston transfers the rotary movement to the

drive ring, which guides the clamping slides into the clamping area.

The clamping function is purely manual. No compressed air is

required. This makes the clamping system extremely flexible and

allows it to be used wherever no pressure medium is available.

Unlocking the clamping system

1 The manually actuated clamping system is unlocked by rotary

movement at the drive piston (item 4) which can be accessed

from the side. Insert the hexagon screwdriver in the hexagon

socket of the drive piston and turn it counter-clockwise.

2 The clamping slides (item 3) move outwards until the final

position of the rotary movement is reached.

3 The clamping pin is unlocked.

The clamping pins are available as separate accessories in four

versions (see chapter 6.4). They are mounted on customized

pallets or devices.

4 The pallet can be removed.

Locking the clamping system

1 The pallet can be inserted in the clamping system as soon as

the clamping slides are unlocked and the rotary movement at

the drive piston has reached the back stop.

2 Insert the pallet in the clamping system.

3 Insert the hexagon screwdriver in the hexagon socket of the

drive piston and turn it clockwise. After a few degrees of

rotation the unlocking position is leaved and the module closes

automatically.

7

7.1

7.2