Assembly

02|NSE-M plus 138 |en

11

Assembly

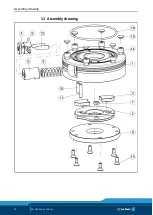

The item numbers to the corresponding individual parts refer to

the drawing in chapter 11.

Access to the drive piston (item 4) on the side must be ensured

during the assembly of the manually actuated quick change

pallet system, in particular in the event of clamped clamping

pallets. Check whether the drive piston is easy to access in order

to open or close the clamping module prior to the installation.

Wear protective equipment (protective gloves and safety shoes).

WARNING

Risk of injury due to falling down of the Quick Change Pallet

System during transport

Transport carefully.

Use a crane and/or a trolley for transport

CAUTION

Risk of injury due to squeezing

Install the Quick Change Pallet System carefully.

Don't get your limps in a gap between moving parts or clamping

fixture of the machine.

General assembly notes

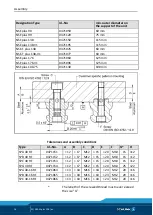

If several clamping units are to be mounted in serial connection,

please make sure that the evenness and deviation in height of the

supporting surfaces from module to module keeps within 0.01 mm

(relating to a depth gauge of 200 mm). The deviation of the

interface position should not exceed ± 0.015 mm.

Due to the redundancy, clamping systems that are lying further

than 160 mm apart from each other or whose positioning

tolerance is not within ± 0.01 mm should use clamping pins with

positioning accuracy in one direction (SPB 40). For clamping

positions which are not used for alignment of the devices or

pallets, clamping pins with centric scope (SPC 40) can be used (see

also chapter 6.4).

6

6.1