Technical data

01.00|ROTA THW vario |en-US

21

Calculating the clamping force and RPM

Missing information or specifications can be requested from the

manufacturer.

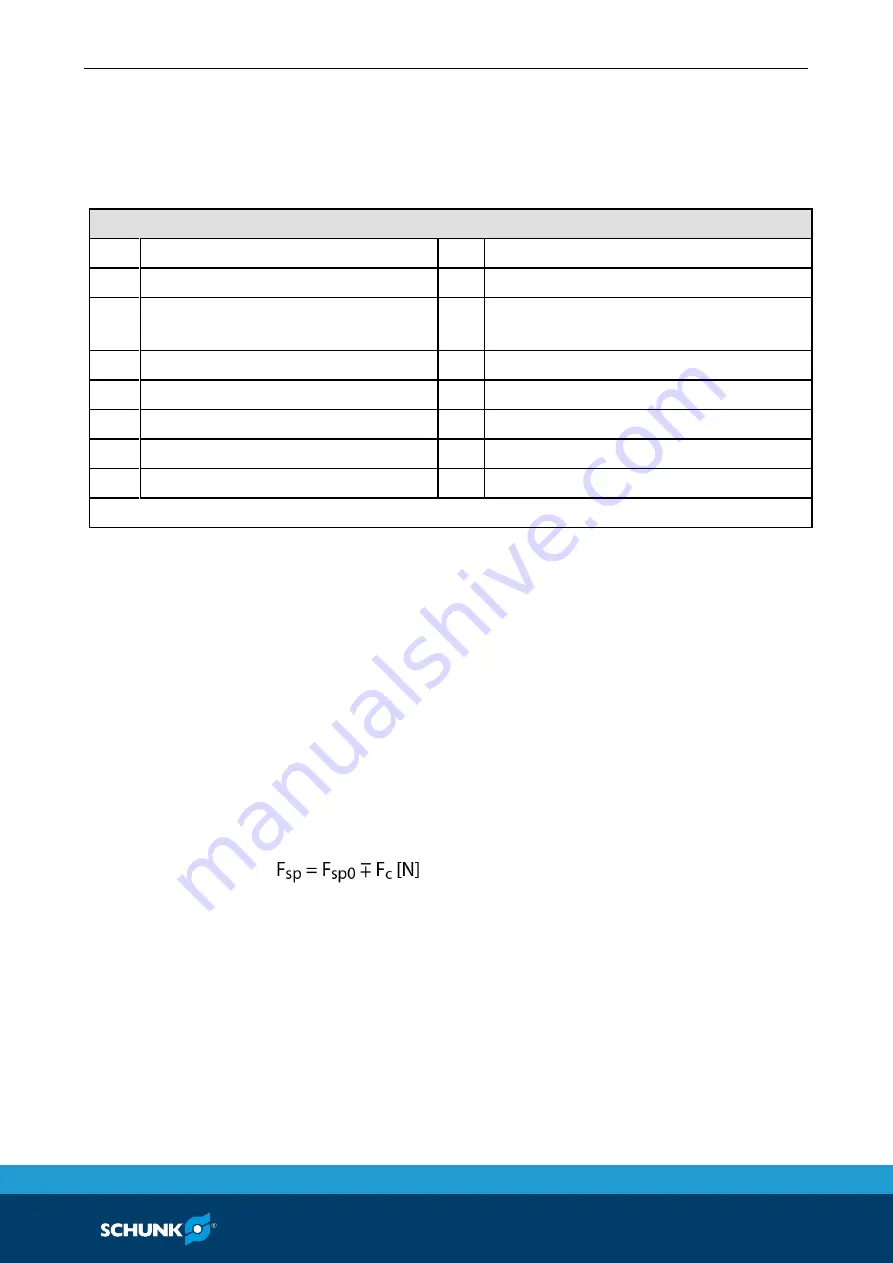

Legend

F

c

Total centrifugal force [N]

M

cAB

Centrifugal torque of top jaws [kgm]

F

sp

Effective clamping force [N]

M

cGB

Centrifugal torque of base jaws [kgm]

F

spmin

minimum required clamping force

[N]

n

Speed of rotation [RPM]

F

sp0

Initial clamping force [N]

r

s

Center of gravity radius [mm]

F

spz

Cutting force [N]

r

sAB

Center of gravity radius of top jaw [mm]

m

AB

Mass of one top jaw [kg]

s

sp

Safety factor for clamping force

m

B

Mass of chuck jaw set [kg]

s

z

Safety factor for machining

M

c

Centrifugal torque [kgm]

Σ

s

Max. clamping force of lathe chuck [N]

kgm × 9.81 = Nm

Calculation of the required clamping force at a specified speed of

rotation

The initial clamping force F

sp0

is the total force impacting radially

on the workpiece via the jaws due to actuation of the lathe chuck

during shutdown. Under the influence of rotation, the jaw mass

generates an additional centrifugal force. The centrifugal force

reduces or increases the initial clamping force depending on

whether gripping is from the outside inwards or from the inside

outwards.

The sum of the initial clamping force

F

sp0

and the

total centrifugal

force F

c

is

the effective clamping force F

sp

.

(–)

for gripping from the outside inwards

(+)

for gripping from the inside outwards

6.3

6.3.1

Summary of Contents for ROTA THWvario

Page 60: ...Assembly drawing 60 01 00 ROTA THW vario en US Assembly drawing ROTA THW vario 215 62 13 13 1 ...

Page 61: ...Assembly drawing 01 00 ROTA THW vario en US 61 ...

Page 62: ...Assembly drawing 62 01 00 ROTA THW vario en US Segmented mandrel ROTA THW vario D 13 1 1 ...

Page 63: ...Assembly drawing 01 00 ROTA THW vario en US 63 Collet chuck ROTA THW vario F 13 1 2 ...