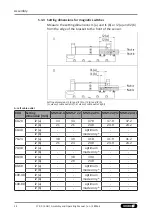

Assembly

1. Check the evenness of the mounting surface,

2. Only open the required air connections (main connection or

3. Connect the product via the hose-free direct connection.

✓

Use O-rings from the accessory pack.

✓

Seal main air connections which are not required with

locking screws.

4. OR: Connect compressed air lines to the main air

connections "A" and "B".

✓

Screw in air connections (plug connections).

OR: Screw on throttle valve in order to be able to perform

sufficient throttling and/or damping.

5. Screw the product to the machine/system,

✓

If necessary, use appropriate connection elements (adapter

plates).

6. Secure the gripper fingers to the base jaws,

7. Connect the sensor, see assembly and operating manual of the

sensor.

8. Mount the sensor,

22].

17

17.00 | KGG | Assembly and Operating Manual | en | 389166

Summary of Contents for KGG 100

Page 1: ...Translation of the original manual Assembly and Operating Manual KGG 2 Finger Parallel Gripper...

Page 49: ......

Page 50: ......

Page 51: ......