8

Operating instructions

Safety light curtain/safety light grid

SLC 420

SLG 420

EN

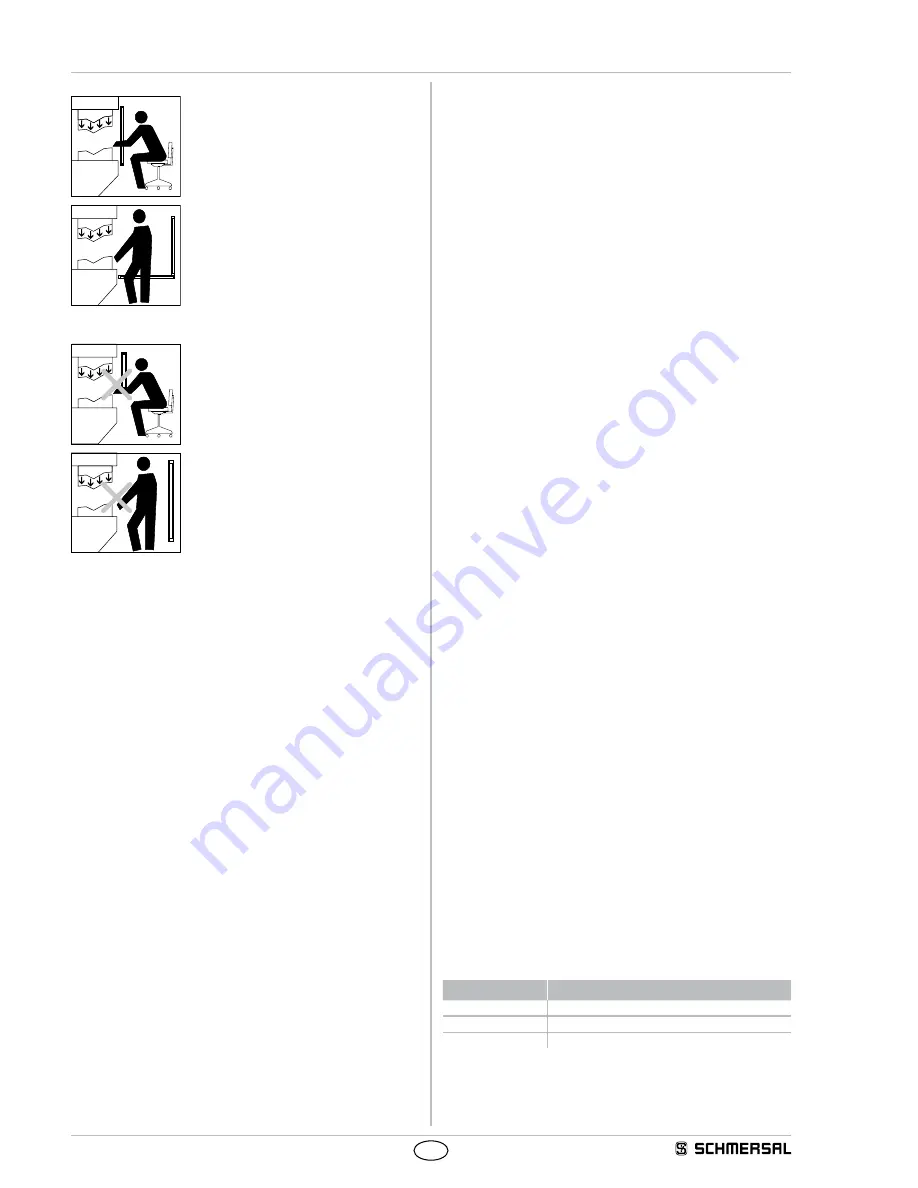

Correct installation

Hazardous machine parts can only be reached

after passing through the protection field

Persons between the protection field and

hazardous machine parts must be prevented

(protection against stepping over)

Unauthorised installation

Hazardous machine parts can be reached

without passing through the protection field

Persons between the protection field and

hazardous machine parts is enabled

3.3 Alignment

Procedure in automatic operating mode:

1 The transmitter and the receiver must be fitted parallel to each other

and at the same height

2 Turn the transmitter and monitor the diagnostic window of the

receiver Fix the light curtain, when the LED OSSD ON (green) is on

and the LED signal reception (orange) is off

3 Determine the max rotating angle to the left and to the right, at which

the LED OSSD ON (green) is on and tighten the mounting screws in

central position Make sure that the LED signal reception (orange) is

not on or flashing

3.4 Setting mode

The alignment of the sensors is carried out using the setting mode

Activating setting mode

If +24 V is on the input (pin 1, receiver) "Release restart interlock" at

system start for at least two seconds (by pressing the button restart),

the system changes over to the setting mode of operation

The signal strength at the receiver is indicated with the signal strength

LED (colour orange) through light pulses The better the alignment, the

higher the frequency of the light pulses The alignment is optimal when

the light pulses switch over to continuous light

If there is no optical synchronisation between the transmitter and the

receiver, a light pulse is emitted every 3 seconds The setting mode is

ended by a system start ( +UB OFF/ON)

Additional signalling with the SLG 420 by the status light

In this mode the signal strength of the beam is signalled to the status

indicator with the lowest value through light pulses (colour yellow)

The better the alignment, the higher the frequency of the light

pulses The alignment is correct when the light pulses switch over to

continuous light

3.5 Safety distance

The safety distance is the minimum distance between the protection

field of the safety light curtain and the hazardous area The safety

distance must be observed to ensure that the hazardous area cannot

be reached before the hazardous movement has come to standstill

Calculation of the safety distance to EN ISO 13855

The safety distance depends on the following elements:

• Stopping time of the machine (calculation by run-on time

measurement)

• Response time of the machine and the safety light curtain and the

downstream relay (entire safety guard)

• Approach speed

• Resolution of the safety light curtain

• Vertical or horizontal installation

Safety light curtain SLC 420

The safety distance for resolutions 14 mm up to 40 mm (vertical

installation) is calculated by means of the following formula:

(1) S = K x T + C [mm]

S = Safety distance [mm]

K = Approach speed 2000 mm/s

T = Total reaction time (machine run-on time, reaction time of the safety

guard, relays, etc)

d = Resolution of the safety light curtain

C = additional distance depending on the resolution,

C = 8 (d - 14) [mm]

If value S <= 500 mm after the calculation of the safety distance, then

use this value

If the value S >= 500 mm then redetermine the distance S using an

approach speed K of 1600 mm/s:

(2) S = 1600 mm/s * T + 8 (d - 14) [mm]

If the new value S > 500 mm, use this value as safety distance

If the new value S

<

500 mm, use a minimum distance of

S = 500 mm

Example:

Reaction time of the safety light curtain = 10 ms

Resolution of the safety light curtain = 14 mm

Stopping time of the machine = 330 ms

S = 2000 mm/s * (330 ms + 10 ms) + 8(14 mm - 14 mm)

S = 680 mm

S = > 500 mm, therefore new calculation with K = 1600 mm/s

S = 544 mm

Calculation of the safety distance for SLG 420 and SLC 420 with a

resolution d > 40 mm

(3) S = ( 1600 mm/s * T ) + 850 mm

S = Safety distance [mm]

T = Stopping time of the m reaction time of the

safety light curtain

K = Approach speed 1600 mm/s

C = Additional distance 850 mm

The following mounting heights must be observed:

Number of beams Mounting height above reference level in mm

2

400, 900

3

300, 700, 1100

4

300, 600, 9001200