6

Operating instructions

Multifunctional safety controller

PROTECT SELECT

PROTECT SELECT OEM

EN

5. Operating principle and settings

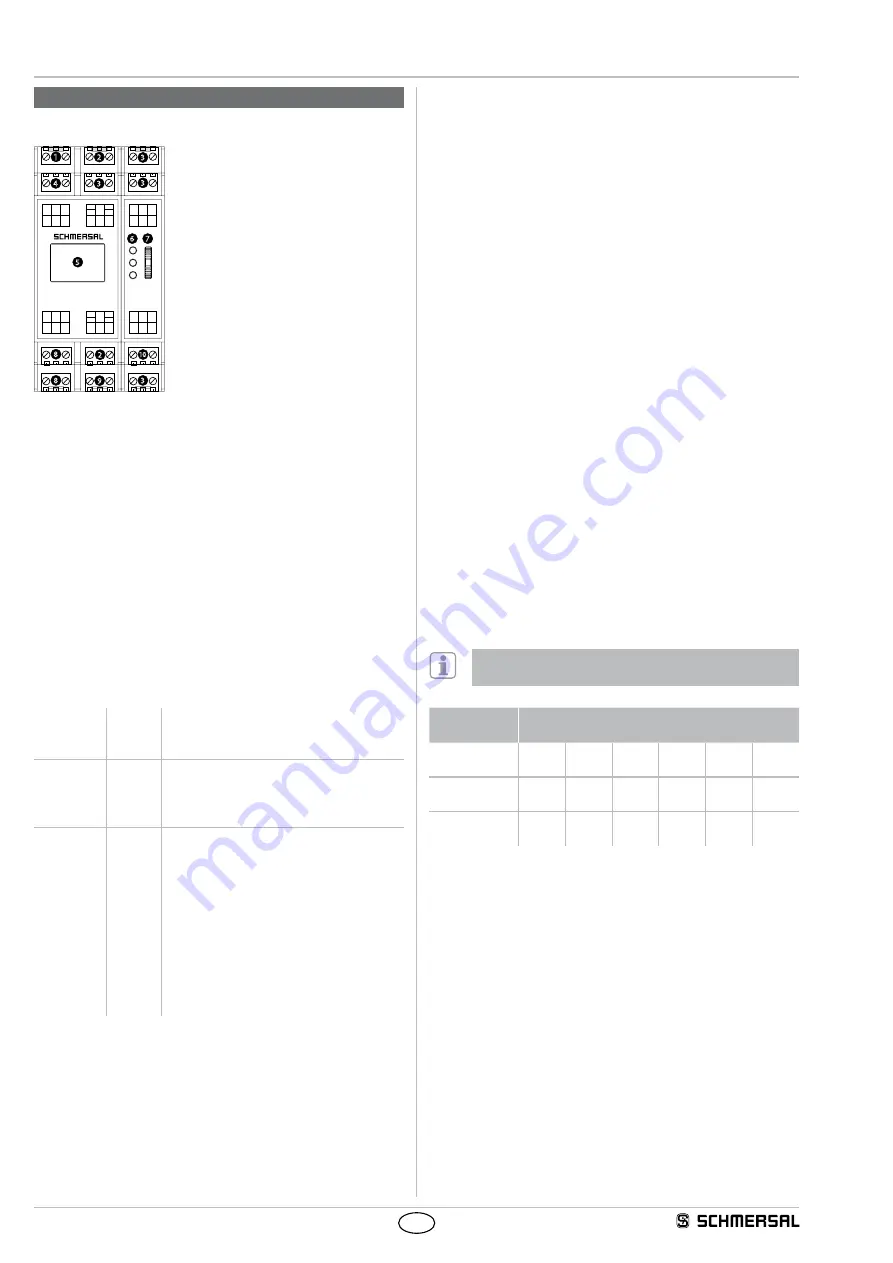

5.1 Connection / operating elements

PROTECT

Run

Q0N

I12

Y2 I13

I14

Y3

T1 T2

A1 A2 FE

I0

Y0 I2

I4

Y1

I1 I3 I5

T0

Q2 Q1

Q0 Q3 Q1N

QR0 QR2

QR1

AI0 AGND AI1

I15 I16 I17

I6 I8 I10

I7 I9 I11

UB

ERR

1

2

2

3

3

3

3

4

5

6

7

8

10

9

8

1 Cycle outputs T0...T2

2 Safe inputs /

optional signalling outputs

3 Safe inputs

4 Supply voltage

5 Graphic colour display

6 Status LEDs

7 Rocker switch

8 Safe semi-conductor outputs

9 Safe relay outputs

10 Safe analog inputs

Operating the rocker switch

Up/down: Navigation through the menu and the input masks.

Press:

Acceptance of the entry or confirmation of an action.

LED indications

U

B

lights up

operating voltage applied

Run

lights up

operating mode

blinking

Configuration mode or module has the factory

defaults (see initial parameterization)

ERR

illuminates A fault is present (safe condition)

blinking

There is a caution or warning

(Operation with possible limitations)

Fault / Warnings / Messages appear on the display in plain text.

Menu structure

The complete structure may be derived from Chapter 7.

5.2 Description of the terminals

Voltage

A1

A2

FE

+24 VDC

0 VDC

functional earth connection

Inputs

I0...I17

AI0

AI1

AGND

Safe digital inputs

Safe analogue input

Safe analogue input

Analogue ground

Outputs

Q0, Q0N

Q1, Q1N

Q2

Q3

QR0

QR1

QR2

Y0...Y3

T0...T2

Safe semi-conductor output p-/n-switching

Safe semiconductor output p-/n-switching

(only available OEM-products)

Safe semi-conductor output p-switching

Safe semi-conductor output p-switching

Supply of safe relay output

Safe relay outputs

Safe relay outputs

Operational outputs (signalling output)

Clock outputs for the supply of safe digital

inputs for short-circuit recognition

5.3 Start level

Alternatively:

auto-start or manual start (falling edge)

Optional:

feedback circuit (EDM), start-up testing

Start-up test

After switching on the supply voltage again the protective device must

first be opened and closed again before the enable can be activated

with the start/RESET button.

5.4 Sensor level

18 safe digital inputs

Selectable:

1-channel of 2-channel, equivalent,

antivalent or deactivated.

Optional condition: Short circuit recognition,

discrepancy monitoring

2 safe analogue inputs

2 analogue safe 1-channel inputs each with 4 adjustable limit values

or 1 analogue safe 2-channel input with 4 adjustable limit values and

adjustable monitoring of the percentage (of maximum value = 4095)

channel deviation.

Discrepancy monitoring

After a request for a 2-channel protection device that is carried out by

only one of the input channels, both input channels must be opened

and closed again before the release with the START / RESET button

can be activated.

Cross-wire detection

Measure for detecting short circuits between the input channels for

2-channel operation. The cross-circuit detection is achieved here by

the use of clock outputs T0 ... T2 using floating safety sensors. The

assignment of the clock outputs to the inputs is fixed. The setting takes

place in the inputs menu.

To reach cat. 4 / PL e / SIL CL 3, cross-circuit detection

must be enabled in floating safety sensors.

Cycle outputs

Digital inputs I00 … I17

(optional signalling outputs Y0 … Y3)

T0 closed

I00

(Y0)

I03

I06

I09

I12

(Y2)

I15

T1 closed

I01

I04

(Y1)

I07

I10

I13

I16

T2 closed

I02

I05

I08

I11

I14

(Y3)

I17

Analogue limit values

The limit values are set with a number of between 0 to 4095.

The following conversion applies:

Limit value = Voltage [V] x 337