Seite:16

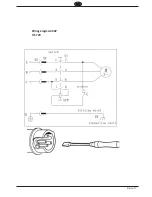

Motor-brake appliance

The brake slowes down the motor of the saw shaft within 10 seconds. The electrical braking is interrupted after maximum

14 seconds.

In case the braking takes more than 10 seconds the machine should not be used again, as the brake is defective. The

machine implicitly needs to be disconnected from the power supply. Only an electronic specialist should be instructed to

repair this malfunction.

The electrical motor is dimensioned for operating mode S 6 - 40 %.

S6 = pass operation with load exposure

40% = related to 10 min. 4min. load; 6min. pass operation

If the motor gets overcharged, it automatically switches off, as a winding thermal switch is built in in the winding of the

motor. After a cool-down period (time varies) the motor can be switched on again.

Defective electrical power supply cords

Electrical power supply cords often suffer insulation damages.

Possible causes:

•Pressure spots, when power supply cords are being led through windows or doors.

•Buckling spots by incorrect attachment or guidance of the power supply cords.

•Cuttings by driving over a power supply cord.

•Insulation damages through pulling out of the socket.

•Cracks in worn-out insulation.

Such defective electrical power suplly cords should not be used and are extremely dangerous because of the insulation

damage.

Check electrical power supply cords on damages on a regular base. Please pay attention that upon checking the power

supply cord is not plugged in. Electrical power supply cords have to comply with the relevant VDE and DIN-regulations. Only

use power cables with the qualification H 07 RN. The type denomination should be imprinted.

There has to be an imprint of the type denomination on the connection cable.

•Extension cables must be up to 25 m long, have a cross cut of 1.5 square millimeter, be over 25 m length, and have a

minimum 2.5 square millimeter.

•The powersupply should be 16 A.

Rotary current motor

•The power supply has to be 380-420 Volt / 50 Hz.

•The power supply and the extension cables must be 5-fold leads = 3 P + N + SL.

•Extension cables must have a minimum cable cross section of 1.5 square millimeter.

•The power supply should be maximum 16 A.

•In case of connection to the power supply or moving site the rotary direction should be checked, otherwise the polarity has

to be changed.

Alternating current motor

•The supply voltage hast to be 220-240 Volt / 50 Hz.

•Extension cables must be up to 25 m long, have a cross cut of 1.5 square millimeter, be over 25 m long, and have a mini

-

mum 2.5 millimeter.

•The power supply should be 16 A.

Connections and repairs of the electrical equipment should only be carried out by an electrical specialist.

In case you have further questions, please specify the following:

•Motor manufacturer

•Current type of the motor

•Information of the machine type label

•Information of the switch type label

If you send the motor back, always return the complete power unit with electro-control.