Installation, Mounting and Maintenance DISA-B

Z11/36 - 8

Construction subject to change.

No return possible!

09.05.2014

Version:

Checks

Prior to commissioning, the following items must be checked or

guaranteed:

During commissioning itself, the following items must be guar-

anteed:

Maintenance

For reasons of safety, the power supply and hydraulic circuit

must be disconnected prior to any maintenance activity. If the

unit was operated in heating mode, you have to wait until the

register has cooled down.

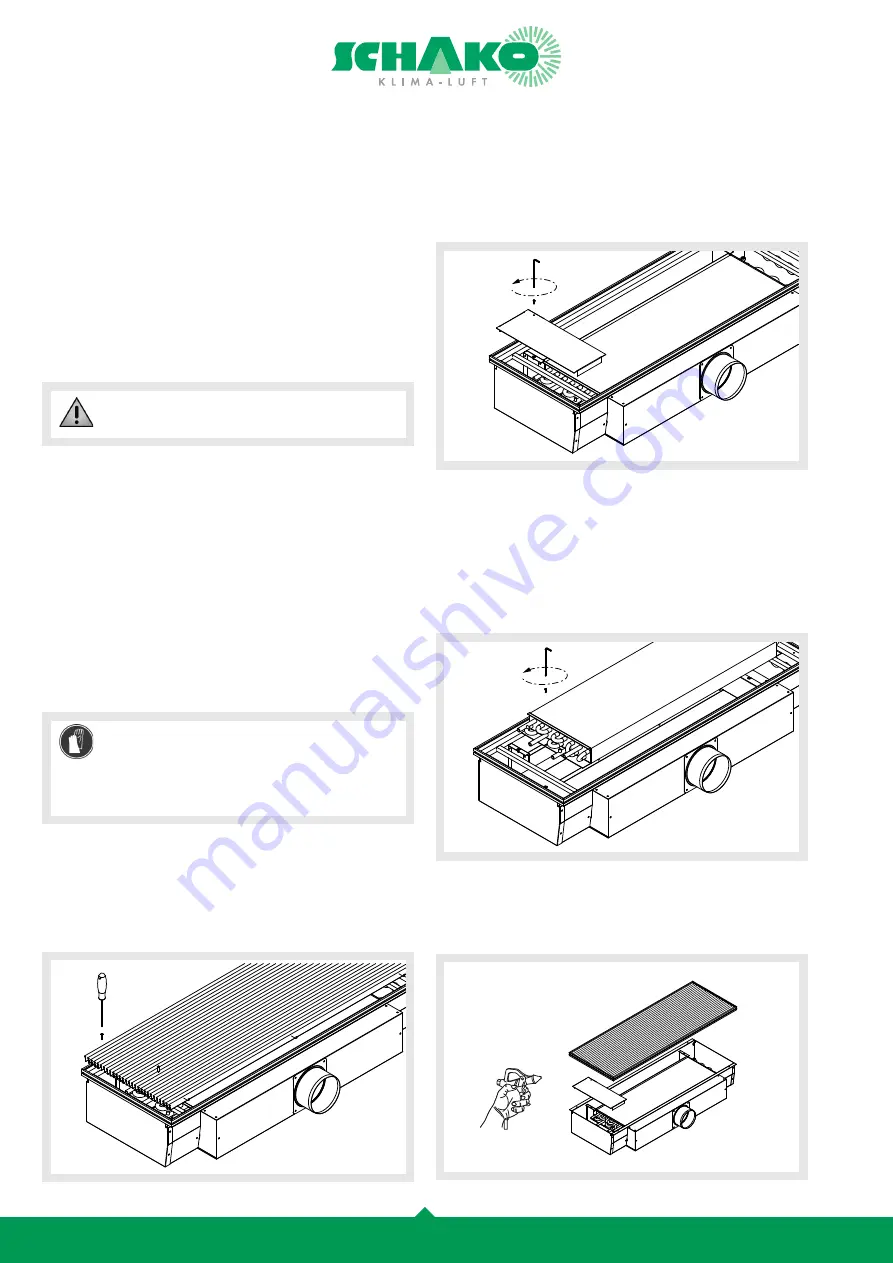

Disassembling the units

PA

Connection covers

Registers

Cleaning the grilles

Clean them with an industrial vacuum cleaner or steam cleaner

or by spraying them with a non-aggressive cleaner.

- Hydraulic connections were tightened properly and exhib-

it no leaks.

- Connecting and fastening elements have been sufficiently

tightened.

- Adequate access for carrying out the maintenance activi-

ties has been provided.

- Use the on-site ventilation device to ensure that no air re-

mains in the register and the circuit.

- The connecting and fastening elements have been suffi-

ciently tightened.

- In heating mode, the temperature of the discharged sup-

ply air is not above 40°C.

- In type PA-3, remove screws and grilles (see figure).

- In type PA-R, roll up the grille and remove it.

After these items have been taken care of,

the correct fastening of the device must be checked.

When performing maintenance activities, it is rec-

ommended wearing personal protective equip-

ment, in order to avoid cuts and other injuries

produced by sharp and pointed parts.

- Remove the screws unscrewing them with an Allen

wrench

- Remove the covers of the hydraulic connections

- Before removing the register, make sure that the hydraulic

circuits are closed.

- Disconnect the register from the hydraulic system.

- Remove the two screws on the register sides unscrewing

them with an Allen wrench and remove the register.