Fire damper BSK-RPR-EU

Technical

documentation

Installation

details

Construction subject to change

No return possible

Version: 2015-02-01 | Document: 09/48 | Page 6

General information

During mounting or installation, there is a risk of injuries.

To avoid any possible injuries, personal protective

equipment (PPE) must be worn.

Fire dampers must be installed such that external forces

do not impair their permanent functioning. During

mounting it might be necessary to provide reinforce-

ments for the housing or the like. The requirement of

statically load-bearing lintels may have to be taken into

consideration.

Improper transport/handling may result in dama-

ge/functional impairment. In addition to that, the film of

the transport packaging must be removed and the de-

livery inspected for completeness.

In storage, fire dampers must be protected from dust,

dirt, moisture and the effects of temperature (e.g. direct

sunlight, heat-emitting light source, etc.). They must not

be exposed to direct effects of the weather and must not

be stored below -40 °C or above 50 °C.

The fire dampers must be protected from dirt and dama-

ge. After installation is complete, any dirt must be remo-

ved immediately.

Enough space must be provided for installation, mortar

lining etc.

Perform a functional check of the fire dampers before

and after mounting and ensure ready access.

Electrical installations or work on electrical components

may only be carried out by skilled electricians. The supp-

ly voltage must be switched off when performing this

work.

INSTALLATION DETAILS

Installation in solid walls

Installation in solid walls (shaft walls, shafts, ducts and fire

walls) made of, for example, concrete, masonry according

to EN 1996 or DIN 1053; solid plaster wall boards accord-

ing to EN 12859 or DIN 18163; apparent density

≥

450

kg/m³ and wall thickness W

≥

150 mm.

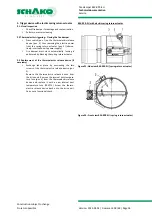

Circumferential gaps "s" must be completely filled with

mortar of category M15 according to EN 998-2, NM II DIN

V 18580 (previously: MG III according to DIN 1053) or fire

protection mortar of suitable grades. The minimum gap si-

ze s

min

is 40 mm (maximum gap size s

max

≤

60 mm).

If the fire damper is installed during the construction of

the wall, the gaps "s" can be omitted. The mortar bed

depth must be designed according to the minimum wall

thickness and may not be less than this thickness. When

performing a mortar lining or a direct installation, make

sure that the housing is not pressed toward the inside

(reinforcement). If necessary, a statically active lintel must

be provided.

The distance of the fire dampers to one another must be

at least 200 mm.

The distance to load-bearing, adjacent components (wall /

solid ceiling) is minimum 75 mm.

Minimum gap size with complete mortar lining

Figure 8: Minimum gap size for complete mortar lining in

solid walls