Fire damper BSK-RPR-EU

Technical

documentation

Spring

return actuators

Construction subject to change

No return possible

Version: 2015-02-01 | Document: 09/48 | Page 11

SPRING RETURN ACTUATORS

Electric spring return actuators B10/B11

B10 (BFL24-T-ST SO), B11 (BFL230-T SO)

Figure

14

: BSK-RPR-EU with electric

spring return actuator

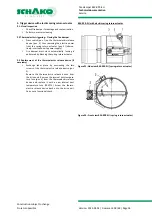

Connection diagram

Spring return actuators B10/B11

Figure

15

: Connecting diagram B10/B11

Electric spring return actuator with thermoelectric release

device BAT.

Trigger temperature (internal duct temperature) 72°C

Operating position (damper "OPEN") and tensioning of

the return spring by applying the supply voltage.

24V actuators with connectors that can be removed on

site if required.

Safety position (damper "CLOSED") through spring

force when supply voltage is interrupted or the tempe-

rature fuses (ambient temperature or internal duct

temperature; 72°) respond. Reaction of the thermal fu-

ses interrupts the supply voltage permanently.

Attention!

Safety function is only guaranteed if the drive has been

connected to the supply voltage in accordance with regula-

tions and unlocked mechanically.

Display of the damper end positions is possible by me-

ans of integrated micro switches via potential-free

changeover contacts (connected on-site) (S1 – S3

"CLOSED" indicates the closed position; S4 – S6 "OPEN"

indicates the opened position)

Manual actuation and fixing in any position is possible

in the de-energised state. It is unlocked manually.

On-site function control is possible by means of the

control key of BAT.

Spare parts: Temperature fuse for temperature inside

the duct (ZBAT72). Exchange takes place by unscrewing

the two screws of the thermoelectric release device.

Remove the thermoelectric trigger device from the dri-

ve unit. Remove the internal duct temperature fuse

from the thermoelectric release device and replace it

with a new internal duct temperature fuse (ZBAT72).

Screw the thermoelectric trigger device back onto the

drive unit.

For any other damage etc., the entire "actua-

tor/thermal release device" must be replaced comple-

tely.

Attention:

24 V connection via safety transformer

B10 (BFL24-T-ST SO)

Plug-in version for

connection to the com-

munication and power

supply unit BKN230-24

Parallel connection of further drives

is possible. Observe specifications.