11

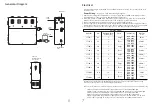

Automatic drain Cord

Automatic drain Valve

Automatic drain Cord Connector

End

"A"

End

"B"

Plumb to Drain

Line in accordance

with Code

Arrow indicates

correct direction

of flow

Drain Valve

Nipple

Plumb to

Drain Line

Automatic

drain

Valve

Plumbing to be performed by a qualified licensed

plumber and shall be in accordance with applicable

national and Local Codes. Unit drains by gravity.

A drain line that is lower than Automatic drain

assembly must be available. The Automatic drain

valve outlet is threaded 15mm. Check plumbing

code for receptor, trap and vent requirements.

Use copper or brass nipple 15mm x

90mm

or

longer (not supplied) to connect the Automatic

drain valve (end "B") to the Drain Valve (valve end

"A" & "B" are indicated on bottom of Automatic

drain Valve).

DO NOT REMOVE THE DRAIN VALVE.

Removal may cause equipment and property

damage. If there is not enough room for the valve,

an elbow and a short nipple (not provided) can

be added.

Installation Instructions

1. Disconnect all power supplied to the unit.

2.

3.

4. Open Drain Valve (handle must be aligned with

brass nipple as shown).

5. Connect the Automatic drain cord connector to the

two pin connector as shown.

Operation

The optional Automatic drain

feature automatically drains the

SAWO system following each

use. the stainless steel tank is

flushed and remains empty

until the steam generator

is used again. A time delay

(about 2 hours) allows the

water to cool down before

it drains resulting in a safe

gentle operation.

Drain Valve

(shown in the correct open position)

DO NOT REMOVE THIS DRAIN VALVE

Steam Generator

Nipple

(copper or

brass nipple

15mm x

90mm

or longer

(not supplied))

DO NOT TURN OR REMOVE THE DRAIN VALVE

Steam Generator

Automatic drain shown fully assembled

NOTE:

For illustrative purposes only.

Do not drain into a steam enclosure or

any location where accidental contact with drain

water may occur. In the event of a power failure, the

Automatic drain valve will open and discharge hot water.

!

WARNING

!

CAUTION

(2) Pin Connector

for Automatic

drain

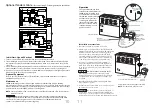

Optional Tandem Cable

-

for connecting 2-5 steam generators in tandem

1. Turn on control. Follow specific instruction sheet provided with controls.

2. Steam will begin to appear in 5 minutes at the steam head. Steam will shut off when desired

temperature is reached and will automatically resume when room temperature drops below

set point.

3. Steam will shut off automaticaly when control counts down to zero. to shut steam off manually,

turn control OFF. To clear steam from enclosure area, turn shower on before opening door.

4. If unit does not start and control does not turn ON (control display does not light up) then turn

breaker off for twenty seconds and try again.

Refer to specific instruction sheets for installation, operation and maintenance of optional

equipment and accessories.

SAWO steambath generators require little maintenance. Other than periodic draining,

maintenance procedures are minimal. Every 2 months, or more often in "hard" water areas, the

manual drain valve should be opened fully flushing out accumulated materials, salts and other

particles which are naturally by-products of boiling water.

NOTE:

Flush a minimum of two hours after the control has been turned off to insure that the

water has cooled.

Draining immediately after a steam cycle may expose PVC and other piping

to high temperature water. Check local requirements. The unit will refill automatically when

the control is activated again. In areas of very hard water, a SAWO automatic drain

system is recommended for generator longevity.

Optional Equipment

Initial Start-Up and Checkout

Maintenance

10

!

WARNING

SECOND UNIT

MASTER UNIT

TO THIRD UNIT

TO FOURTH UNIT

TO FIFTH UNIT

C

C

FUSE

GROUND

CONTACTOR

WATER

FEED

SOLENOID

VALVE

RELAY 1

CONTROL

BOARD

CONTROL

TEMP

SENSOR

AUTO

DRAIN

TO

PROBE

TRANSFORMER

L N

G

HEATING

ELEMENT

S

C

C

FUSE

GROUND

CONTACTOR

WATER

FEED

SOLENOID

VALVE

RELAY 1

CONTROL

BOARD

CONTROL

TEMP

SENSOR

AUTO

DRAIN

TO

PROBE

TRANSFORMER

L N

G

HEATING

ELEMENT

S

STS

230V 1N~

kW

KATSO OHJEIST

A

BEACHTEN SIE DIE

ZUSÄTZLICHEN

WICHTIGEN

ANWEISUNGEN IN DER

BEDIENUNGSANLEITUNG

READ THE

MANUAL

FOR

ADDITIONAL

IMPOR

TANT

INSTRUCTIONS

LÄGG MÄRKE

TILL DE

VIKTIGA